What is an Air Compressor and Dryer Combo and How Does It Work

An air compressor and dryer combo gives you both compressed air and moisture removal in one system. Moisture in compressed air can damage tools and products. Many industries use these combos, with the global market reaching USD 5.6 billion in 2023. Sollant provides reliable solutions for your business.

Protects equipment from water damage

Improves air quality for production

Table of Contents

Key Takeaways

An air compressor and dryer combo provides clean, dry compressed air, protecting tools and improving product quality.

Using this combo system saves space and simplifies installation, making it a cost-effective solution for various industries.

Regular maintenance, such as checking filters and draining condensate, ensures optimal performance and longevity of the system.

Air Compressor and Dryer Combo Basics

What Is an Air Compressor and Dryer Combo?

You get a complete solution when you choose an air compressor and dryer combo. This system combines two main components: an air compressor and a dryer. The air compressor draws in air and increases its pressure. The dryer removes moisture from the compressed air before it reaches your tools or production line.

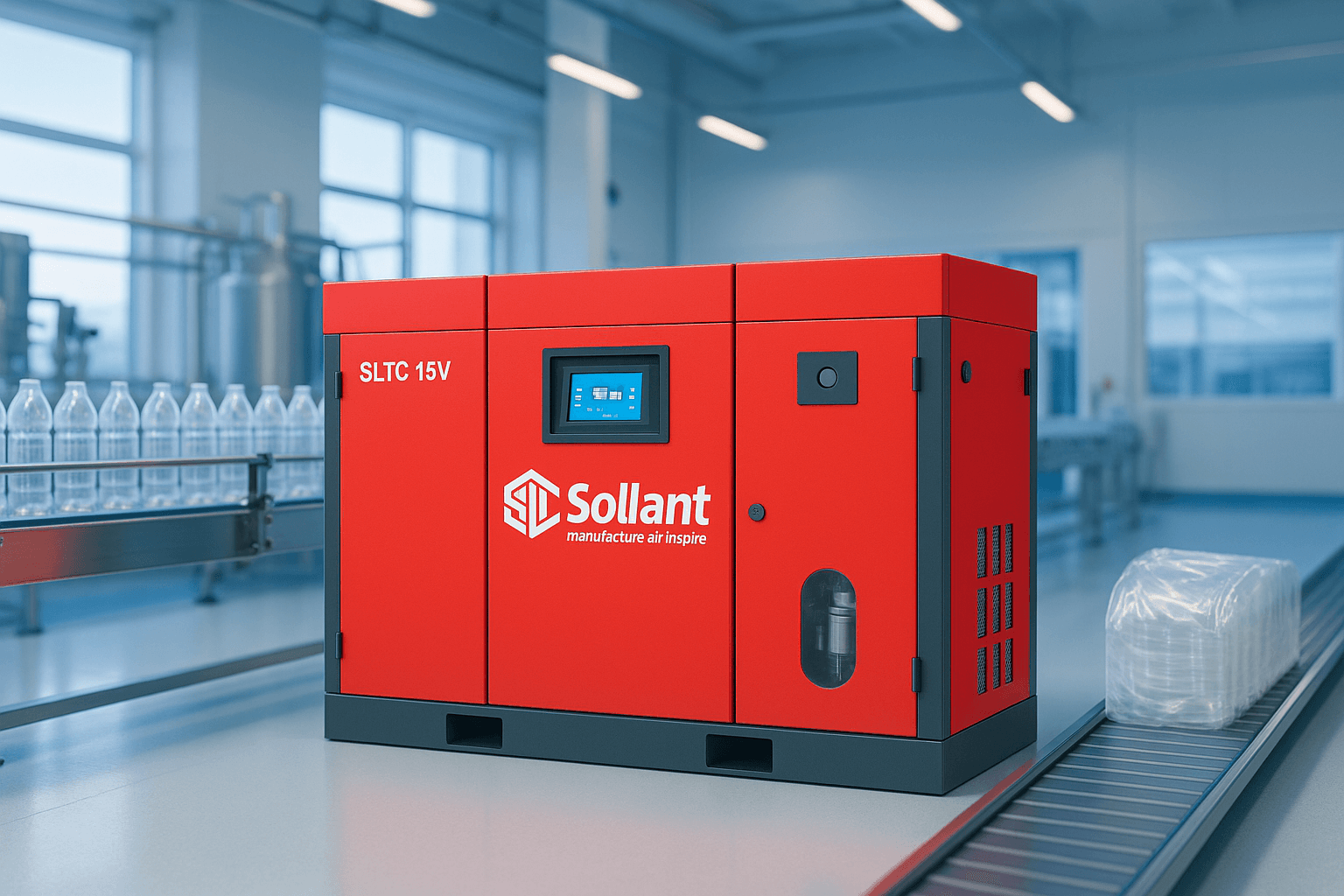

Sollant designs these combo systems to deliver reliable performance. You benefit from advanced technology, energy-saving features, and a wide range of models. Sollant offers oil-free, variable speed drive, and custom options to fit your needs. You can trust Sollant’s experience in exporting and supporting customers worldwide.

Tip: A combo unit saves space and simplifies installation. You only need one system to get clean, dry compressed air.

Why Use Air Compressors and Dryers Together?

Moisture in compressed air creates serious problems for your equipment and products. Water in compressed air can cause corrosion, damage sensitive instruments, and lead to costly repairs. Excess moisture may also contaminate your final products, especially in industries like food processing and painting.

You avoid these risks when you use air compressors and dryers together. The dryer removes moisture, so you get dry, high-quality compressed air every time. Here are some benefits:

Improves product quality in painting, food processing, and other applications.

Reduces maintenance costs by protecting machinery from wear and tear.

Prevents freezing and blockages in cold environments.

Moisture can also lead to:

Malfunctions in instruments and controls.

Ice build-up in colder climates, which blocks piping and creates safety risks.

Staining, dilution, and contamination of products.

Many industries rely on air compressor and dryer combo systems. You see these combos in manufacturing, automotive, electronics, and more. Sollant serves customers in these fields, helping them maintain high standards and reliable operations.

Industry | |

|---|---|

Laser Cutting | Cooling the resonator and optics |

Welding | Ensuring clean, dry air for optimal welding performance |

Plasma Generation | Maintaining equipment efficiency |

Microelectronics Manufacturing | Preventing product defects due to moisture |

Food Processing | Ensuring product safety and quality |

Pharmaceutical Production | Meeting strict quality standards |

Shot Blasting | Improving surface preparation |

Painting and Coating | Achieving high-quality finishes |

Printing | Preventing equipment malfunction |

Sollant stands out as a leading manufacturer and exporter in the air compressor and dryer combo market. You benefit from their focus on energy efficiency, advanced technology, and customized solutions. Sollant’s one-stop service and commitment to cooperation help you achieve better results in your business.

How a Compressed Air Dryer Works

Step-by-Step Process

You need to understand how a compressed air dryer removes moisture from the air. The process involves several important steps that ensure you get clean, dry compressed air for your equipment.

Cooling the Air: After the air leaves the compressor, it is hot and full of water vapor. The system uses an aftercooler to lower the temperature. This step removes about 70% of the water vapor as the air cools and water condenses.

Drying the Air: The cooled air then enters the air dryer. Here, the dryer reduces the moisture content even further. This step lowers the dew point, which means water will not form droplets in your pipes or tools.

Moisture Separation: The air dryer separates the condensed water from the air. The system drains the water away, so only dry air moves forward.

Final Filtration: Some systems use filters to catch any remaining particles or oil. This step ensures the compressed air dryer delivers the highest quality air possible.

Note: Removing moisture at each stage protects your equipment from rust, corrosion, and other damage.

Main Types of Compressed Air Dryers

You can choose from several types of compressed air dryer systems. Each type uses a different method to remove moisture and suits different needs.

Type of Dryer | How It Works | Best For |

|---|---|---|

Refrigerated Dryer | Cools air to condense water vapor, then drains the liquid | General industrial use |

Uses materials like silica gel to adsorb moisture from the air | Applications needing very dry air | |

Chemical Dryer | Uses chemicals that absorb water vapor | Low-volume or portable applications |

Membrane Dryer | Passes air through a membrane that lets water vapor escape | Sensitive or specialty applications |

Refrigerated air dryers: These are the most common. They work like a refrigerator, cooling the compressed air so water vapor turns into liquid. The system then drains the water away. You get reliable performance and easy maintenance. Most manufacturing and automotive shops use this type.

Desiccant air dryers: These use special materials to attract and hold water vapor. The system often has two towers. While one tower dries the air, the other regenerates. This type gives you extremely dry air, which is important for electronics, pharmaceuticals, or any process that cannot tolerate moisture.

Chemical (Deliquescent) air dryers: These use chemicals that absorb water from the air. They are simple and do not need electricity, but you must replace the chemicals regularly.

Membrane air dryers: These use a special membrane to let water vapor pass through while keeping the air molecules inside. They are quiet and compact, perfect for labs or sensitive equipment.

Tip: Choose the compressed air dryer that matches your dew point needs and maintenance preferences.

Comparing Refrigerated and Adsorption (Desiccant) Dryers

Feature | Refrigerated Air Dryers | Adsorption Air Dryers |

|---|---|---|

Efficiency | Cost-effective, easy to maintain | |

Dew Point | Around 35°F | As low as -40°F |

Application Suitability | General use, not for ultra-dry needs | Ultra-dry air for sensitive applications |

Maintenance | Low | High |

You should use a refrigerated air dryer for most standard industrial tasks. If you need ultra-dry air, such as for electronics or pharmaceuticals, an adsorption (desiccant) dryer is the better choice.

Sollant Air-Dryer-for-Air-Compressor Features

Sollant designs air dryer solutions that help you achieve reliable and efficient compressed air systems. You benefit from several key features:

High Efficiency: Sollant compressed air dryer units remove moisture quickly and thoroughly. This protects your equipment and improves product quality.

Stable and Reliable Operation: Sollant air dryers work in a wide range of environments. You can count on consistent performance, even in high-temperature or high-pressure settings.

Energy Savings: Sollant focuses on energy-efficient designs. You save on operational costs while reducing your carbon footprint.

Easy Maintenance: Sollant air dryers use quality components and smart design. You spend less time on maintenance and more time on production.

Industry Applications: Sollant compressed air dryer systems serve manufacturing, automotive, food processing, electronics, and more. You get clean, dry air that meets strict industry standards.

Custom Solutions: Sollant offers a variety of models and can customize systems for your unique needs. You always find the right fit for your operation.

Sollant air dryers help you prevent corrosion, reduce energy use, and keep your production running smoothly. You protect your investment and ensure high-quality results every day.

If you want a compressed air dryer that delivers performance, reliability, and value, Sollant gives you a solution you can trust.

Choosing and Maintaining Your Combo

Key Benefits

When you use an air dryer and compressor combo, you gain many advantages. The system improves air quality, protects your equipment, and saves space. You also lower your energy bills and reduce downtime. Here is a quick look at the main benefits:

Benefit | Description |

|---|---|

Enhanced Air Quality | The air dryer removes moisture and contaminants, keeping your tools safe. |

Space and Cost Savings | One unit does the job of two, saving floor space and money. |

Improved Reliability | The combo reduces breakdowns and keeps your system running smoothly. |

You only need to service one system, making your job easier. | |

Energy Efficiency | The air dryer helps lower your power use and costs. |

Versatility | You can use the combo in many industries and applications. |

You also meet strict standards like ISO 8573.1 and HACCP, which are important for food and pharmaceutical production.

Installation and Maintenance Tips

Proper installation and care keep your air dryer working at its best. Place your combo in a clean, cool room to control temperature and reduce noise. Make sure air flows freely around the air dryer.

Always check that filters are clean and that drains work well. Blocked filters or faulty drains can cause water to build up and damage your system.

Follow this simple maintenance schedule:

Drain condensate and check oil levels daily.

Clean intake vents and test safety systems weekly.

Inspect for leaks and change air dryer filters monthly.

Keep a log of all maintenance tasks. This helps you spot problems early and plan future service.

Selecting the Right System

When you decide how to choose the right air dryer, think about your air quality needs, the amount of air you use, and your work environment. If you need very dry air, pick a system with a desiccant air dryer. For general use, a refrigerated air dryer works well. Check the size of your space and the power supply.

Sollant offers expert advice and strong after-sales support. Their distributor network helps you find the best air dryer for your business. You get reliable help from installation to daily use.

You gain reliable, dry compressed air with an air compressor and dryer combo. Sollant’s solutions help you boost energy efficiency and cut waste.

System automation and improved controls save energy and lower your carbon footprint.

Different combos meet unique needs in many industries.

Select the right dryer type.

Size your system correctly.

Review total ownership costs.

Use pre-filters.

Maintain your system regularly.

Explore Sollant’s website for expert support and the best combo for your business.

FAQ

What maintenance does an air compressor and dryer combo need?

You should check filters, drain condensate, and inspect for leaks regularly. Clean the system and replace worn parts as needed to keep performance high.

Can you use a combo unit in any industry?

You can use a combo unit in many industries. Manufacturing, automotive, food processing, and electronics all benefit from clean, dry compressed air.

How do you choose the right dryer type?

Assess your air quality needs. Choose a refrigerated dryer for general use. Select a desiccant dryer if you need ultra-dry air for sensitive applications.