Essential Tips for Maintaining Your Air Compressor for Laser Cutting Machines

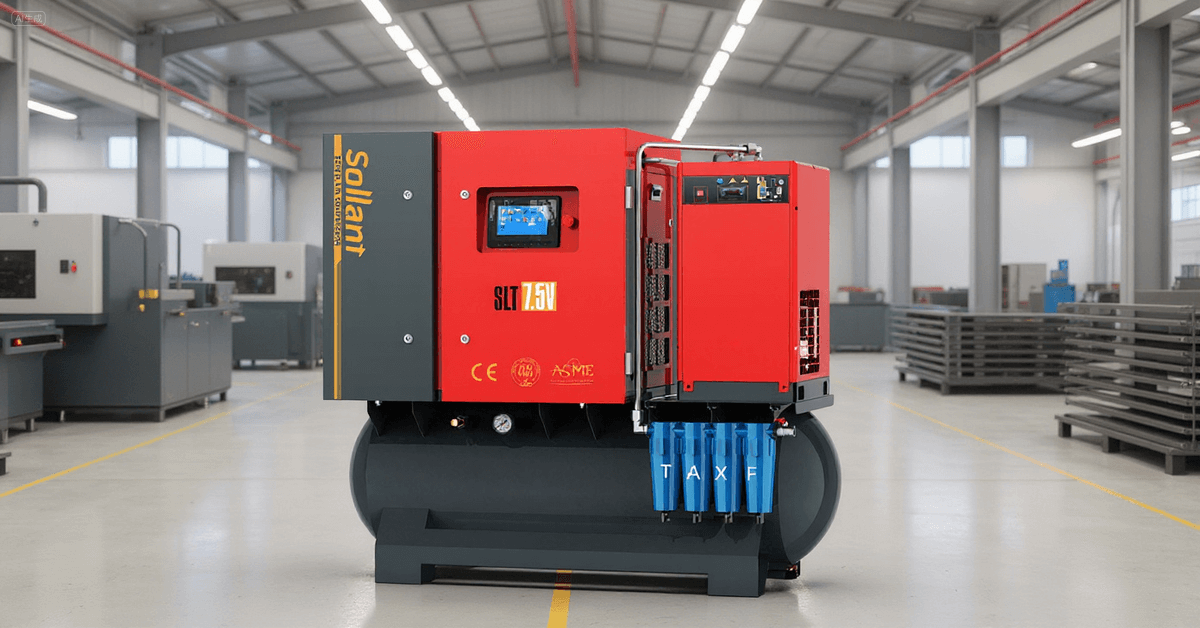

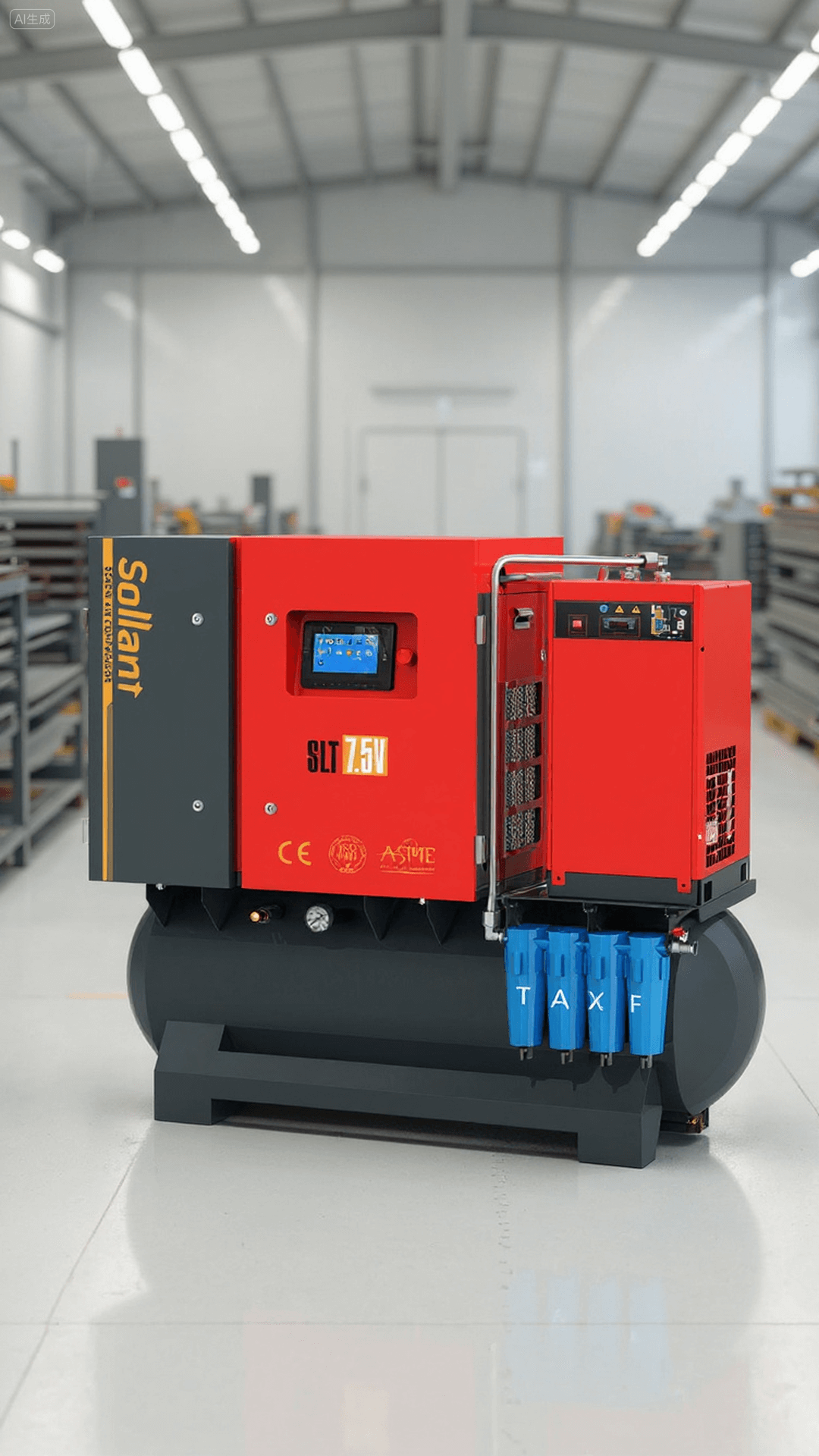

You should keep your air compressor for laser cutter working well. This helps the machine run smoothly and last longer. Clean it often, like you would with a screw-air-compressor from sollant. Cleaning stops expensive problems and keeps dirt and oil out. Easy checks and simple steps make it work better and stop it from breaking down.

Table of Contents

Key Takeaways

Check your air compressor often to find problems early. Watch for leaks, listen for strange noises, and check the air pressure. This helps your machine work well.

Clean the outside of your compressor every three months. Dust can block cooling fins. This can make it too hot and work less well.

Drain water from your air compressor every day. This stops rust and keeps the system clean. It also helps you avoid expensive repairs.

Routine Checks

Visual Inspection

Begin each day by looking at your air compressor for laser cutter. Check hoses and fittings for leaks. Make sure bolts are tight. Listen for strange or loud sounds. Loud noises can mean parts are worn out or loose. If air pressure is low, the air filter might be clogged. There could also be a problem with the pressure regulator. If air flow changes a lot, there may be leaks or a dirty filter.

Tip: Looking at your machine often helps you find problems early. This keeps your machine working well.

Here is a table that lists problems you might see when you look at your machine:

Issue | Description |

|---|---|

Low Air Pressure | This can happen if the air filter is clogged, there are leaks, or the pressure regulator is not working. |

Excessive Noise | This can mean some parts are worn out, loose, or not put together right. |

Inconsistent Air Flow | This can be caused by a dirty air filter, a bad pressure regulator, or leaks in the air system. |

Clean Exterior

Keep the outside of your air compressor for laser cutter clean. Dust and dirt can cover the cooling fins and vents. This makes it hard for the compressor to cool down. If it gets too hot, it does not work as well. Some parts can even break.

Dust on cooling fins keeps heat from leaving. The compressor gets hotter and does not work as well.

Too much dust can lower air pressure and cause more problems inside.

Follow these steps to clean the outside:

Use a soft cloth or brush to wipe away dust and dirt.

Use compressed air or a soft brush to clean the cooling fins and vents.

Make sure the air intake filters are clean and not blocked.

Note: Clean the outside of your compressor every three months. Remove dust from the cooling fins often. Check moving parts to make sure they are lined up and have enough oil. Test the electrical parts and tighten any loose connections.

Drain Condensate

Water builds up inside your air compressor for laser cutter when you use it. You need to drain this water often. If you do not, water can collect and cause rust, corrosion, and other issues.

Here is a table that shows what can happen if you do not drain the water:

Consequence | Description |

|---|---|

Rust | Too much water can cause rust and corrosion. This can hurt pipes and connectors. |

Impurities | Water can mix with the air and make the system dirty. This can lower how well it works. |

Ice buildup | Too much water can freeze and block air paths. This stops the machine until you fix it. |

Damaged circuit | Water can cause short circuits. This can break parts and make the system not last as long. |

Poor lubrication | Water can make the oil not work right. This can make the machine get too hot and not work well. |

Tip: Drain the water from your compressor every day. This keeps your machine clean and helps you avoid costly repairs.

Filter and Oil Maintenance

Air Filter Care

You need to keep the air filter clean on your air compressor for laser cutter. A dirty air filter lets dust and debris get inside. This can lower the quality of your laser cuts and make the machine work harder. Clean the air filter every 500 hours of use. If you work in a dusty area, check it more often.

Here is a table that shows what happens when the air filter gets clogged:

Description | |

|---|---|

Debris | Increases the likelihood of contaminants entering the system, affecting cut quality. |

Residue buildup | Leads to reduced performance and increased maintenance costs. |

Heat created by the machine | Can result in inconsistent production levels due to overheating. |

Tip: Clean the air filter regularly. This helps you avoid problems with cut quality and keeps your machine running smoothly.

You can follow these steps to clean the air filter:

Turn off the air compressor for laser cutter.

Remove the filter cover.

Take out the filter and tap it gently to remove dust.

Use compressed air to blow out any remaining dirt.

Put the filter back and secure the cover.

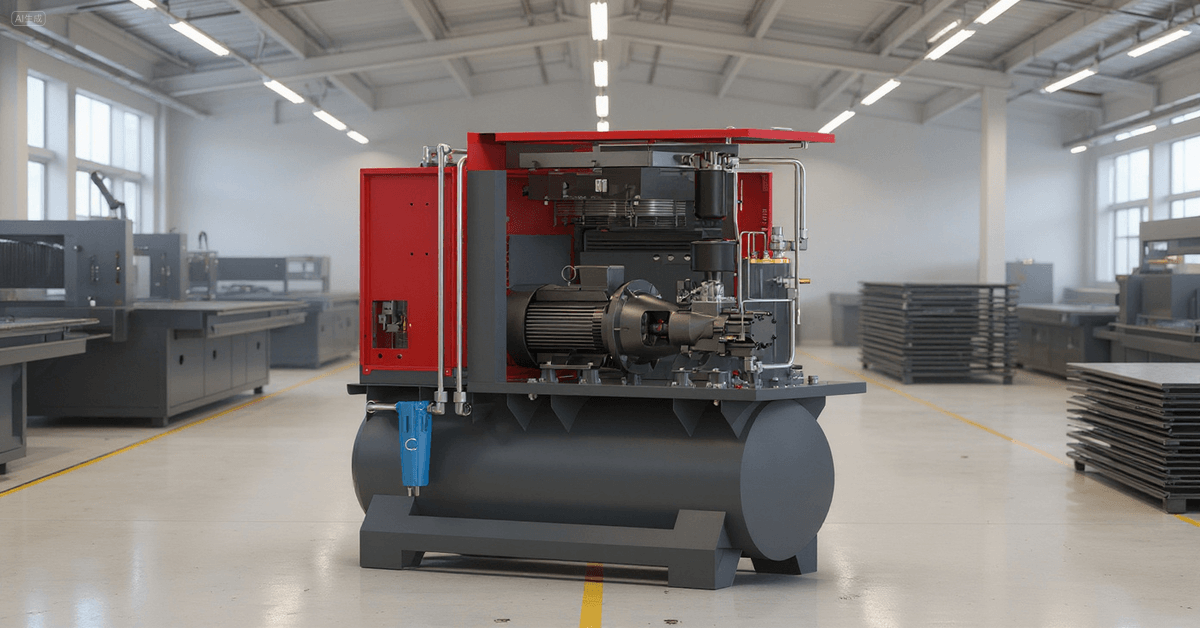

Oil Level Check

Check the oil level in your air compressor for laser cutter often. Oil keeps the moving parts working smoothly. Low oil can cause damage and make the machine wear out faster. Look at the oil sight glass or dipstick before you start the machine each day.

Here is a table that shows what can happen if you do not keep the oil level right:

Description | |

|---|---|

Excessive stress and friction | Results from poor lubrication, leading to increased wear. |

Rapid wear of mechanical components | Causes a reduction in the lifespan of the air compressor. |

Catastrophic breakdowns | Can occur from using unsuitable oils, leading to failure. |

Note: Always use the oil recommended by the manufacturer. Check the oil level before each use. Add oil if it is low. Never run the compressor without enough oil.

Oil Filter Replacement

Replace the oil filter on your air compressor for laser cutter at the right time. The oil filter keeps dirt and metal pieces out of the oil. If you do not change it, dirty oil can damage the machine.

Manufacturers suggest you replace the oil filter after 3,000 hours of use. If you have a new compressor, change the oil filter after 500 hours. Here is a table that shows when to replace the oil filter:

Component | Replacement Interval |

|---|---|

Oil Filter | After 3000 Hours |

New Compressors | After 500 Hours |

Tip: Write down the hours each time you change the oil filter. This helps you remember when to do it next.

You can follow these steps to replace the oil filter:

Turn off and cool down the compressor.

Remove the old oil filter.

Put on a new filter and tighten it.

Check for leaks after you start the machine.

Regular filter and oil maintenance helps your air compressor for laser cutter last longer. Clean filters and fresh oil keep the machine working well and help you avoid expensive repairs.

Belt and Valve Care

Belt Inspection

You should check the belts on your air compressor for laser cutter often. Belts connect the motor to the compressor pump. If a belt gets loose or worn, your machine will not work well. You can spot problems early by looking for cracks, fraying, or shiny spots on the belt. Press the belt gently to see if it feels tight. If it moves too much, you need to adjust it.

Proper belt tension keeps your compressor running smoothly. If the belt is too loose or too tight, you may face several problems. The table below shows what can happen when the belt tension is not right:

Consequence | Description |

|---|---|

Belt slippage | Reduces efficiency and increases energy use because the belt does not grip the pulley well. |

Overheating | Extra friction causes the belt and pulley to get too hot. |

Premature failure | Inconsistent performance and strong vibrations wear out parts faster. |

Tip: Check the belts and pulleys every month. Adjust the tension if needed. Replace any belt that looks damaged.

Valve Check

Valves control the flow of air in your compressor. You need to make sure they work right to keep your laser cutter safe and efficient. Intake valve seals can wear out over time. Pressure relief valves protect your system from too much pressure.

Inspect the intake valve seal every 4,000 hours of use. Replace it if you see damage or leaks.

Check the sealing ring of the intake valve seal every 4,000 hours. Change it if it looks worn.

Test the pressure relief valve often to make sure it opens and closes as it should.

Note: Regular valve checks help prevent air leaks and keep your compressor safe. Write down when you inspect or replace any valve parts. This helps you remember your maintenance schedule.

Safety and Upgrades

Power Off Before Maintenance

Always turn off your air compressor for laser cutter before fixing it. Unplug the power so the machine is fully off. Let out all the air pressure from the system. Lock and tag the power switch so no one turns it on by mistake. Keep the machine away from any pressure sources. Close the outlet valve and let out air before you connect or remove anything.

Here is a table that lists safety steps:

Safety Protocols | Description |

|---|---|

Disconnect Power | Unplug the compressor before maintenance. |

Lock Out/Tag Out | Use lock out/tag out procedures to prevent accidental startup. |

Bleed Air Pressure | Release all air pressure before working on the compressor. |

Shut Off Air Source | Turn off the air source and bleed pressure before maintenance. |

Isolate Tools | Remove and isolate tools from the compressed air system. |

Close Outlet Valve | Close the outlet valve and depressurize before making changes. |

Isolate Machine | Separate the machine from all pressure sources before removing parts. |

Tip: Doing these things keeps you safe and protects your machine.

Consider Oil Coolers

Oil coolers help your air compressor for laser cutter stay cool. Good oil coolers move heat away from the compressor. This stops it from getting too hot and breaking. When heat is managed well, your compressor works at the right temperature. It lasts longer and does not break as much. You will spend less money fixing parts and have fewer problems.

Oil coolers keep the compressor cool and safe.

Good heat control helps your compressor last longer.

Less damage means you pay less for repairs.

If you want better upgrades, look for brands like sollant. Sollant has oil coolers that fit many air compressors for laser cutting machines.

Use Larger Air Tanks

Getting a bigger air tank can help your laser cutting work. A large tank gives steady airflow for long jobs. You can cut faster and get smoother edges. Using compressed air instead of other gases saves money. Cleaning the laser lens and cutting head often helps your machine last longer.

Here is a table that shows why bigger tanks are good:

Benefit | Description |

|---|---|

Improved Cutting Speed | Faster operation with steady compressed air. |

Improved Edge Quality | Smooth edges without burrs. |

Lower Operating Costs | Compressed air costs less than oxygen or nitrogen. |

Extended Machine Lifespan | Regular cleaning and maintenance keep your equipment working longer. |

Constant Airflow | Larger tanks provide consistent airflow for long cutting sessions. |

Note: Sollant has air compressors with bigger tanks for laser cutting machines. These upgrades help you get better results and save money over time.

Maintenance Scheduling

Set Routine Intervals

You should set clear intervals for maintaining your air compressor for laser cutter. Regular checks keep your machine stable and efficient. A good schedule helps you avoid sudden breakdowns and keeps your laser cutting quality high. Here is a simple routine you can follow:

Inspect for leaks and worn parts every week.

Clean filters and drain moisture at least once a week.

Monitor pressure levels before each use.

Lubricate moving parts as the manufacturer suggests.

Keep the area around the compressor clean at all times.

Following a set schedule improves cutting speed and reduces downtime. Your machine will last longer and cost less to repair.

Assign Responsibilities

Assigning clear duties helps everyone know what to do. You can make a list of tasks for each team member. When everyone takes part, your air compressor for laser cutter stays in top shape. Teamwork also builds awareness and pride in keeping the equipment running well.

Give each operator a checklist for daily and weekly tasks.

Ask team members to check the fan unit and clean the impeller fan.

Rotate duties so everyone learns each part of the process.

A shared approach means no step gets missed. Your team will spot problems early and fix them fast.

Keep Records

Keeping good records helps you track what you have done and what needs attention. Use a logbook or digital tool to write down each maintenance task. Record the date, what you checked, and any issues you found. This habit helps you plan future work and spot patterns.

Task | Date | Operator | Notes |

|---|---|---|---|

Filter cleaned | 2024-06-01 | Alex | No issues |

Oil checked | 2024-06-02 | Jamie | Added 100ml oil |

Belt inspected | 2024-06-03 | Taylor | Slight wear, monitor |

Good records make it easy to show maintenance history. You can prove your air compressor for laser cutter gets the care it needs.

Taking care of your air compressor helps your laser cutting machine last longer. It also saves you money. You can find problems early and stop breakdowns. This means you pay less for repairs. Use this checklist to help you remember what to do:

Frequency | |

|---|---|

Turn off and drain air tank | Before all maintenance |

Drain water from storage tank | 3–8 times a day |

Clean air filter | Every half month |

Replace filter element | Every 1200 hours |

Add grease to crankshaft bearing (oil-free models) | Every 1000 hours |

Check manual for special steps | As needed |

If you follow these steps often, your machine will break less. It will work better every day.

FAQ

How often should you drain water from your air compressor?

You should drain water daily. This prevents rust and keeps your compressor working well. Check the tank after each use for best results.

What oil should you use in your air compressor?

Always use the oil recommended by your compressor’s manufacturer. Using the wrong oil can cause damage and reduce the machine’s lifespan.

Why does your air compressor make loud noises?

Loud noises often mean loose parts or worn belts. Inspect your compressor right away. Tighten bolts and replace damaged belts to fix the problem.