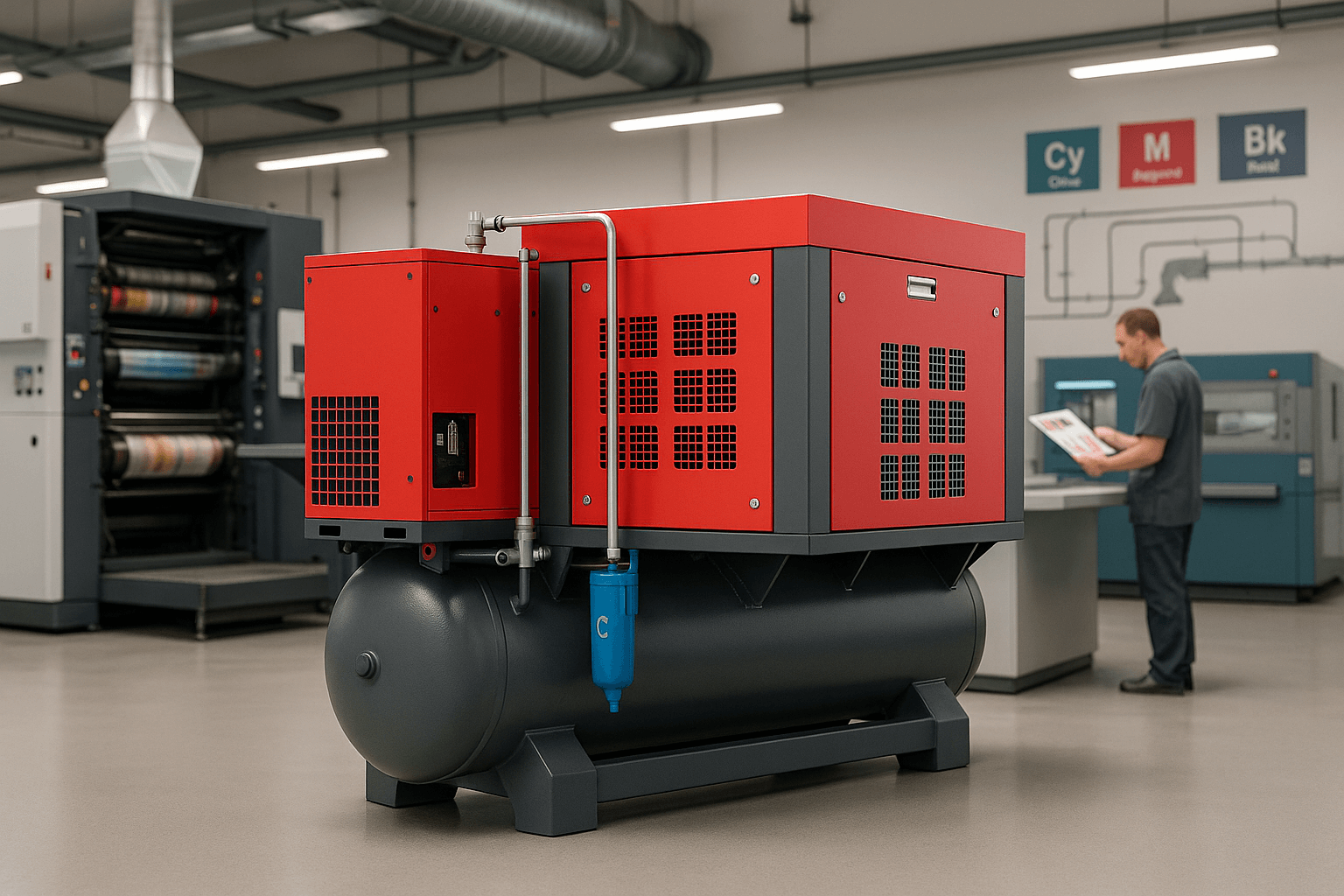

Simple Ways to Keep Your Screw Air Compressor Running Smoothly

You want your screw air compressor to run reliably every day. Simple, routine checks make this possible. Proactive maintenance prevents costly breakdowns and reduces operating costs by extending equipment life. Using high-quality parts from Sollant further boosts efficiency. Anyone can follow these steps to keep operations steady.

Table of Contents

Key Takeaways

Regular maintenance prevents costly breakdowns and extends the life of your screw air compressor. Follow a routine schedule to catch small issues before they escalate.

Monitor key parameters like pressure, temperature, and oil quality. Keeping these in check ensures efficient operation and reduces energy costs.

Use high-quality parts from Sollant to enhance durability and performance. Quality components lead to fewer repairs and lower operating expenses.

Why Maintenance for Screw Air Compressors Matters

Preventing Downtime

You rely on your screw air compressor to keep your operations running without interruption. Regular maintenance helps you avoid the most common causes of downtime, such as:

Compressor failing to start or stop

Air leaks that reduce pressure

Electrical motor and power issues

Pressure and flow problems

Excessive noise or vibrations

If you neglect routine checks, you risk facing unexpected shutdowns. Overheating, oil leaks, and loss of pressure can halt production and lead to expensive repairs. By following a maintenance schedule, you catch small problems before they become major failures. Sollant understands how critical uptime is for your business. That’s why Sollant designs compressors and parts for maximum reliability, helping you minimize unplanned downtime.

Boosting Efficiency

A well-maintained screw air compressor uses less energy and delivers consistent performance. When you keep filters clean and oil at the right level, you prevent varnish buildup and oil degradation. This keeps operating temperatures stable and reduces energy waste. In fact, energy costs can make up more than 75% of the total cost of owning a compressor. Poor maintenance drives these costs even higher.

Tip: Using high-quality parts, like those from Sollant, means you benefit from advanced materials and precision engineering. These features improve durability, reduce wear, and keep your compressor running efficiently even in tough environments.

Maintenance Impact | Description |

|---|---|

Regular Maintenance | Extends the lifespan of the compressor and saves money. |

Neglecting Maintenance | Causes early wear and higher energy bills. |

Sollant’s commitment to energy-saving solutions ensures you get the most out of every maintenance effort, supporting both your productivity and your bottom line.

Key Parameters to Monitor

Keeping your screw air compressor in top condition starts with monitoring a few essential parameters. By checking these values regularly, you can spot problems early and keep your equipment running efficiently. Sollant compressors make this process easier with advanced monitoring features that help you maintain stable operation.

Pressure and Temperature

You should always keep an eye on both pressure and temperature. These two parameters tell you a lot about the health of your screw air compressor. If either value moves outside the recommended range, you risk damaging your equipment or reducing its efficiency.

Parameter | Optimal Range |

|---|---|

Operating Pressure | |

Discharge Pressure | 10-11 barg (145-160 psig) |

Optimal Temperature | 50-55°C (122-131°F) |

Tip: If the outlet temperature rises above 60°C (140°F), you should insulate the piping to protect personnel and prevent heat loss.

Abnormal pressure or temperature readings can signal several issues:

Low pressure may mean a blocked intake filter or a stuck inlet valve.

High pressure could indicate a clogged discharge line or reduced air demand.

High temperatures speed up oil aging and can cause the compressor to overheat.

Low temperatures, especially below 40°F, can lead to frozen condensate, cracked components, and blocked drains.

Sollant compressors use precise sensors and digital displays to help you track these values in real time. This technology allows you to react quickly if something goes wrong, reducing the risk of costly downtime.

Oil Level and Quality

Oil is the lifeblood of your screw air compressor. You need to check both the oil level and its quality to ensure smooth operation. Low oil levels can cause excessive wear, while dirty or degraded oil can damage internal parts.

Oil Type | Change Interval |

|---|---|

Mineral oil | |

Synthetic oil | Every 8,000 hours or more |

Heavy-duty apps | Adjust as needed |

You should keep the oil level between the minimum and maximum marks on the sight glass. If the oil looks dark, milky, or smells burnt, it is time to change it. Using low-quality or old oil can lead to:

Poor lubrication and increased friction

Oil emulsification from water contamination

Higher energy use and unstable performance

Rust, corrosion, and sludge buildup

More frequent maintenance and higher costs

Sollant compressors use high-density, nano-plated filter materials that keep oil clean and extend service intervals. Their advanced filtration systems help you avoid common oil-related problems and keep your compressor running longer.

Electrical Readings

Electrical health is just as important as mechanical health. You should monitor current, voltage, and power consumption to ensure your screw air compressor operates safely and efficiently.

Reading Type | Importance |

|---|---|

Pressure | Ensures tools operate at required levels, prevents energy waste, and reduces wear. |

Temperature | Indicates compressor performance; high temperatures can damage tools and degrade lubricants. |

Oil Levels | Essential for compressor operation; regular checks prevent excessive wear and unplanned shutdowns. |

Power Consumption | Helps understand operational efficiency and demand management. |

Vibrations | Monitoring can reveal leaks or system issues, crucial for maintaining efficiency. |

Abnormal electrical readings can point to serious issues:

High current may mean the compressor is overloaded or has worn bearings.

Low voltage or bad contactors can cause electrical failures.

Unusual vibration or power spikes may signal leaks or mechanical faults.

Sollant compressors feature smart controllers that monitor these electrical parameters automatically. You receive alerts if anything moves outside the safe range, allowing you to act before a minor issue becomes a major problem.

Note: Regular monitoring of these key parameters helps you prevent breakdowns, reduce maintenance costs, and extend the life of your screw air compressor. Sollant’s advanced monitoring technology gives you peace of mind and supports stable, efficient operation.

Essential Component Checks

Routine inspection of your screw air compressor’s core components ensures reliable performance and extends equipment life. You can prevent most failures by focusing on four key areas: air filters and intake systems, oil separators and filters, cooling systems, and valves and connections. Sollant’s advanced engineering and high-density, nano-plated filter materials set a new standard for durability and efficiency in these critical components.

Air Filters and Intake System

Clean air is essential for compressor longevity. You should inspect and maintain air filters and the intake system regularly to prevent dust and debris from entering the compressor. Clogged filters restrict airflow, reduce efficiency, and increase wear on internal parts.

Recommended Maintenance Intervals:

Maintenance Task | Interval |

|---|---|

Change Filter Kit | |

Change Oil | Every 3,000 hours or 12 months |

Replace Fan and Intake Valve | Every 15,000 hours or 48 months |

Weekly: Clean or change inlet filters and test controls.

Monthly: Clean heat exchangers and inspect belts and hoses.

Every 1,000–2,000 hours (or 6 months): Change filters, log operating conditions, and tighten connections.

Tip: Sollant’s high-density, nano-plated filter materials offer superior resistance to chemical solvents and high temperatures. These filters maintain uniform aperture and low resistance, ensuring clean air intake and longer service intervals.

Oil Separator and Filters

Oil separators and filters play a vital role in maintaining air purity and protecting your compressor’s internal components. You should monitor these parts for signs of wear or failure.

Signs That Oil Separator or Filter Needs Replacement:

You notice increased oil consumption and need to add oil more often.

Visible oil mist appears at discharge points or in condensate drains.

Differential pressure rises gradually, indicating saturation.

Sudden spikes in differential pressure suggest possible structural failure.

High-pressure shutdowns occur due to excessive differential pressure.

Massive oil carryover leads to downstream contamination.

Sollant’s customizable oil separator solutions use nano-plated filter elements that resist deformation and maintain high cleanliness. These features help you minimize oil carryover and extend the lifespan of your screw air compressor.

Note: Regularly check the differential pressure across the oil separator. Replace the separator element if you observe abnormal readings or oil mist at the discharge.

Cooling System

The cooling system prevents overheating and ensures stable operation. Poor maintenance can lead to frequent overheating, which causes unnecessary wear and shortens the compressor’s lifespan.

Best Practices for Cooling System Maintenance:

Regularly clean the cooler to remove dust and debris.

Use compressed air to clean cooler fins and maintain proper airflow.

Check coolant levels and clean radiators to ensure efficiency.

Inspect fans and motors to confirm they function correctly.

Alert: Sollant’s cooling systems are designed for easy cleaning and robust heat exchange. Consistent maintenance of these components helps you avoid costly repairs and keeps your compressor running efficiently.

Valves and Connections

Valves and connections control airflow and maintain system integrity. Leaks, loose fittings, and worn gaskets are common issues that can reduce efficiency and cause pressure loss.

Issue Type | Description |

|---|---|

System leaks | Damaged or worn components, loose fittings, or worn gaskets. Inspect for leaks and replace damaged components. |

Loose fittings | Tighten any loose fittings to prevent air loss. |

Worn gaskets | Replace any worn gaskets to ensure proper sealing. |

Leaks often occur at fittings, hoses, or manifolds. Apply liquid soap and water to connections and look for bubbles. Listen for the hiss of escaping air.

Tighten loose connections and replace damaged seals, gaskets, or hoses as needed.

Sollant’s compressors feature robust, customizable connections and valves that withstand demanding industrial environments. Regular inspection and timely replacement of these parts help you maintain optimal performance and prevent air loss.

Tip: Schedule weekly visual inspections and annual pressure gauge calibration to ensure all connections remain secure and leak-free.

By following these essential component checks and using Sollant’s advanced parts, you can maximize the reliability and efficiency of your screw air compressor. Consistent maintenance reduces downtime, lowers operating costs, and supports stable production.

Safety and Environment

Safe Operation Practices

You must prioritize safety every time you operate your compressor. Start with a pre-start checklist. Inspect all equipment and safety devices before use. Always follow the manufacturer’s recommended startup and shutdown procedures. Provide comprehensive training for everyone who works with the compressor. Equip operators with personal protective equipment (PPE) such as gloves and safety glasses.

Check that the compressor is properly grounded to prevent electrical hazards. Use motors with at least an IP44 protection rating to guard against dust and moisture. In high-risk areas, ensure anti-static and explosion-proof features are in place. Regularly inspect the minimum pressure valve and test temperature sensors to confirm they work correctly. Keep protective covers in place to prevent accidental contact with moving or hot parts. Place emergency equipment, like fire extinguishers, nearby and make sure everyone knows how to use them.

Tip: Sollant compressors include certified temperature switches and robust safety features to help you maintain a secure work environment.

Room and Environmental Checks

A clean, well-ventilated compressor room supports reliable operation. Keep the room temperature between 50°F and 85°F. Temperatures above this range can cause mechanical issues, while temperatures below 40°F may lead to oil thickening or freezing. Good ventilation removes hot exhaust air and brings in clean, dry intake air. This prevents overheating and reduces maintenance needs.

Maintain a tidy environment to avoid dust and debris buildup. Contaminants can harm the compressor and lower efficiency. Check that the room stays dry and free from clutter. Proper air circulation and ambient temperature help minimize downtime and extend equipment life.

Sollant focuses on safety and sustainable operation. Their compressors are designed for easy maintenance and reliable performance, even in demanding environments.

Creating a Maintenance Schedule

Routine Checklist

A clear maintenance schedule helps you keep your screw air compressor in top condition. Regular checks prevent unexpected failures and extend equipment life. Use the following table as a guide for routine tasks:

Interval | Tasks | Parts Involved |

|---|---|---|

Daily | Check oil, drain condensate, inspect gauges | Oils, drains, gauges |

Weekly | Inspect filters, belts, couplings, safety valves | Filters, belts, valves |

Monthly | Replace oil filters, clean coolers, inspect dryers | Oil filters, dryer elements |

Quarterly | Change oil, replace intake filters, inspect bearings | Oils, intake filters, bearings |

Annually | Replace separators, belts, coolant; inspect piping | Separators, belts, coolant |

Tip: Following this schedule reduces downtime and keeps your compressor running efficiently. Sollant offers advanced parts and expert support to help you stay on track.

Signs of Trouble

Stay alert for warning signs that signal immediate attention is needed. Early detection allows you to act before a small issue becomes a major problem. Watch for these red flags:

Changes in air pressure consistency

Unusual noises from the compressor

Increased moisture or leaks in the system

Frequent overheating

Repeated shutdowns

Ignoring these symptoms can lead to costly repairs and lost productivity. Investigate any unusual sounds or performance drops right away. Sollant’s service team can help you diagnose and resolve issues quickly, ensuring your operations remain stable.

Note: Regular maintenance and quick response to warning signs protect your investment and support long-term reliability.

Regular maintenance keeps your screw air compressor running smoothly, prevents breakdowns, and extends equipment life. Using quality parts and following a schedule—like Sollant recommends—makes upkeep simple and effective. Start your routine today and contact Sollant for expert support or customized solutions.

Component | Task | Interval |

|---|---|---|

Oil Level | Check/top off | Daily |

Intake Filter | Inspect/replace | Monthly/as needed |

FAQ

How often should you service your screw air compressor?

You should follow the maintenance schedule in your manual. Sollant recommends daily checks and professional servicing every 3,000 hours for optimal performance.

What are the signs your compressor needs immediate attention?

Watch for sudden pressure drops, loud noises, or overheating. If you notice these, stop the compressor and contact Sollant support for expert help.

Can you use non-original parts for maintenance?

Using original Sollant parts ensures the best fit and reliability. Non-original parts may reduce efficiency and shorten your compressor’s lifespan.