Sollant Air Compressor Technical Design Advantages | R&D Technical Standards

When choosing an industrial air compressor, safety, efficiency, and reliability are non-negotiable. Sollant air compressors stand out because they are designed and manufactured according to the world’s highest R&D technical standards, ensuring long-term stable performance, energy efficiency, and absolute safety for your operations.

Table of Contents

1.R&D TECHNICAL STANDARDS:

Our pressure vessels can be custom designed and manufactured to comply with the ASME Boiler & Pressure Vessel Code. This demonstrates the ultimate safety and reliability of our pressure-containing components, effectively preventing risks and ensuring the safety of your personnel and equipment.

We can also custom-certify our air compressor electrical systems to UL certification, meaning every circuit, component, and insulation material has undergone the world’s most stringent safety testing. We completely eliminate electrical fire hazards, ensuring electrical safety under all operating conditions and providing strong support for your product liability insurance.

Our products fully comply with all EU CE directives (such as the Machinery Directive, the Low Voltage Directive, and the Electromagnetic Compatibility Directive).

2.SOLLANT AIR COMPRESSOR EQUIPMENT DESIGN SPECIFICATIONS” FAC TORY DESIGN STANDARDS.

Cooling System Design Standards: The enlarged fan and heat exchanger design far exceeds comparable designs, allowing operation at ambient temperatures below 60°C. The design standard is 45°C ambient and 90°C exhaust temperature.

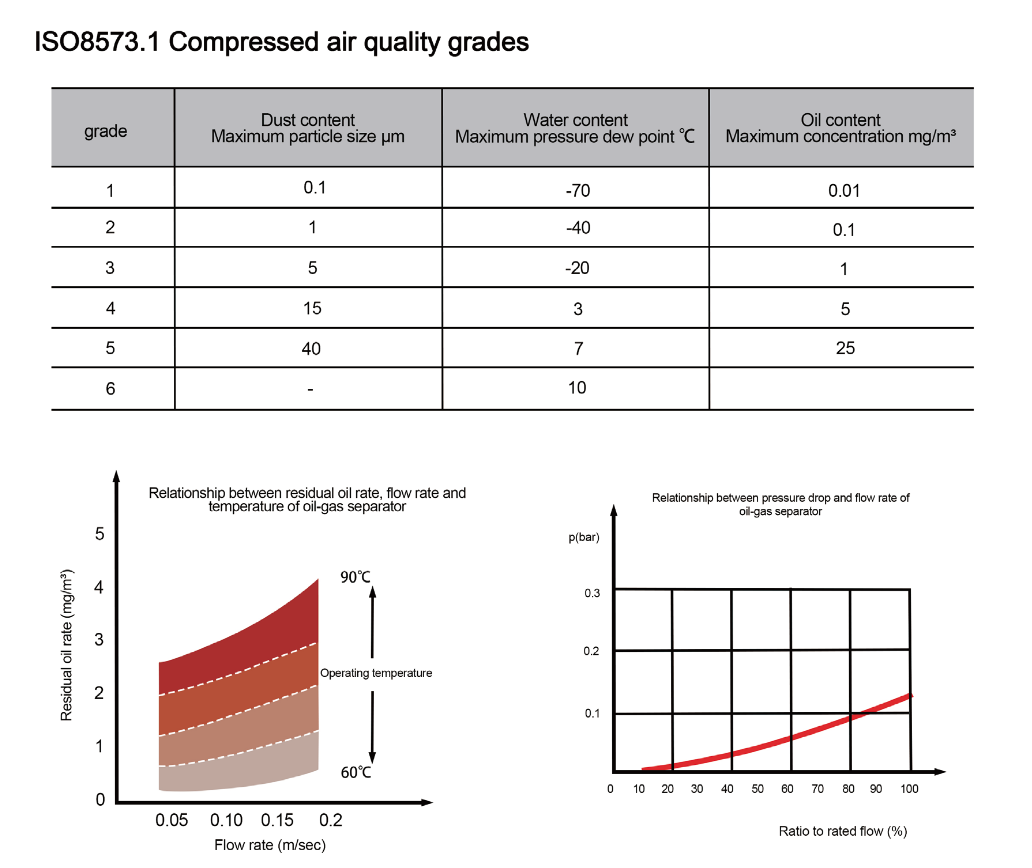

Oil Separator System Design Standards: Under standard operating conditions, at a 0.7 MPa exhaust pressure, the pressure drop of a new oil separator is approximately 0.1-0.25 bar, and the residual oil rate can be controlled between 1-3 ppm. The oil separator lifespan is approximately 4000 hours. This lifespan depends on many factors, including the oil separator design, regular maintenance, environmental cleanliness, operating temperature, and the quality of the oil, air filter, and oil filter.

Contactor selection:

Selection standard power frequency; rated current * service factor * 1.5

Motor current margin:

Service factor S.F1.2 will leave a 10% margin

Service factor S.F1.3 will leave a 15% margin

(1) Motor efficiency is as high as over 96%, and the power factor is 0.99, far exceeding the Class 1 energy efficiency standard;

(2) F-class insulation, 70K temperature rise design, suitable for high temperature working conditions under air compressor

working conditions;

(3) Fully enclosed IP55 protection level, protects the clean environment inside the motor, and extends the life of permanent

magnets and insulation;

(4) Synchronous fan cooling ensures long-term low-frequency safe operation of the motor;

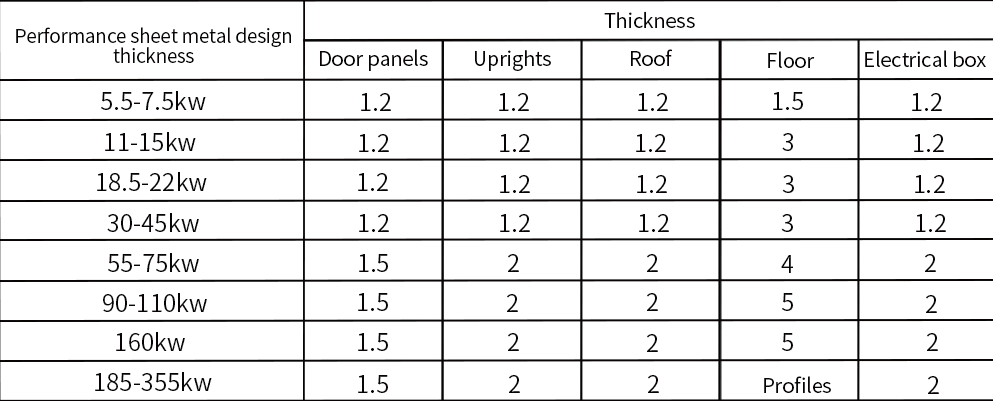

Sheet metal design thickness standard:

Why Choose Sollant Air Compressors?

By following strict international R&D standards and advanced engineering design principles, Sollant ensures that every air compressor delivers:

-

Superior energy efficiency

-

Maximum safety and reliability

-

Long-term cost savings through reduced downtime and maintenance

If you are looking for an industrial air compressor that combines global certifications, advanced cooling, oil separation, and motor technology, Sollant Air Compressors are the ultimate choice.