What Is a Rotary Screw Compressor and How Does It Work

A rotary screw compressor uses twin rotors that spin in opposite directions to draw in and compress air, delivering a steady and efficient supply for industrial systems. Its continuous operation and high durability make it the preferred choice for about 38.6% of industrial facilities worldwide. Many factories rely on models like the 11kw Rotary Screw Air Compressor for demanding environments. Sollant, a trusted China factory, offers The advantages of Sollant 7.5kw industrial air com, meeting diverse industry needs.

Table of Contents

Key Takeaways

- A rotary screw compressor uses two spinning rotors to compress air continuously, providing steady and efficient airflow for industrial use.

- There are oil-injected and oil-free types; oil-injected models are cost-effective but need regular maintenance, while oil-free models deliver pure air for sensitive industries.

- Variable speed compressors save energy by adjusting power to match air demand, reducing costs and environmental impact.

- Rotary screw compressors are reliable, quiet, and last longer than piston compressors, making them ideal for heavy-duty, continuous operation.

- Sollant offers high-quality rotary screw compressors with advanced features, strong quality control, and options to fit various industrial needs.

Rotary Screw Compressor Basics

Definition

A rotary screw compressor is a type of gas compressor that uses a rotary positive-displacement mechanism. This design features two closely meshing spiral rotors, often referred to as the male and female rotors. These rotors compress air by reducing the volume of trapped pockets along their length, resulting in a continuous and steady flow of compressed air. The male rotor typically has convex lobes, while the female rotor contains concave cavities. The precise alignment and shape of these rotors are essential for efficient operation and minimal leakage. This compressor operates without valves, which allows for high-speed performance and reduced vibration compared to traditional piston compressors.

Note: The continuous compression process in a rotary screw compressor leads to less pulsation and noise, making it ideal for industrial environments that require reliable and quiet operation.

Key Components

| Component | Role in Operation |

|---|---|

| Airend | Houses the two interlocking rotors that trap and compress air, serving as the core compressor element. |

| Intake Valve | Regulates the volume of air entering the airend, opening or closing based on system demand. |

| Motor | Provides mechanical power to drive the airend rotors by converting electrical energy. |

| Oil Filter | Removes contaminants from oil to ensure clean lubrication and cooling of components. |

| Air Filter | Cleans incoming air by removing dust and particulates to protect internal components. |

| Separator Tank | Separates oil from compressed air, recycling oil back into the system and sending clean air onward. |

| Fan | Cools the compressor by forcing ambient air through the cooler to prevent overheating. |

| Exchanger/Cooler | Cools compressed air after separation to prepare it for downstream use. |

| Controller | Monitors and optimizes compressor operation, controls start/stop, and protects against faults. |

| Coupling | Connects motor to airend, transferring mechanical power efficiently while reducing vibration. |

| Contactor | Electrically controls power flow to the motor, enabling compressor start and stop. |

Each component plays a vital role in ensuring the rotary screw compressor delivers reliable, efficient, and clean compressed air for industrial applications.

How It Works

The rotary screw compressor operates on the positive-displacement principle. The process begins when ambient air enters through the intake valve. The air filter removes dust and debris, protecting the internal system. Inside the compression chamber, the male and female rotors rotate in opposite directions. As these rotors turn, they trap air in the spaces between them. The volume of these air pockets decreases as the rotors mesh, which compresses the air and increases its pressure.

In oil-injected models, oil is introduced during compression. The oil cools and lubricates the rotors, seals the compression chamber, and helps collect contaminants. After compression, the air-oil mixture moves to the separator tank, where oil is removed and recycled. The clean, compressed air then passes through a cooler to reduce its temperature before use.

- The rotary screw compressor provides a continuous supply of compressed air, which is essential for many industrial processes.

- The absence of valves and the use of two rotors allow for high efficiency, steady airflow, and reduced maintenance needs.

- The design supports both oil-injected and oil-free variants, making it adaptable for industries with strict air purity requirements.

Tip: Regular maintenance of filters, oil levels, and cooling systems ensures optimal performance and extends the lifespan of the rotary screw compressor.

Types

Rotary screw compressors come in several types, each designed to meet specific operational needs and industry standards. Understanding these variations helps users select the right model for their application.

Oil-Injected

Oil-injected rotary screw compressors inject oil directly into the compression chamber. The oil lubricates the rotors, seals internal gaps, and absorbs heat, which improves efficiency. However, this process introduces some oil contamination into the compressed air, requiring filtration before use. These compressors suit heavy industry and general manufacturing, where trace oil is acceptable.

| Aspect | Oil-Injected Rotary Screw Compressors | Oil-Free Rotary Screw Compressors |

|---|---|---|

| Lubrication Method | Oil injected into compression chamber for lubrication, sealing, cooling | No oil in compression chamber; uses non-contact rotors, special coatings, or water injection |

| Air Quality | Some oil contamination requiring multi-stage filtration; typically ISO Class 1 air quality | Truly oil-free air, achieving ISO Class 0 purity suitable for sensitive industries |

| Cooling | Oil acts as heat transfer medium; oil cooler and aftercooler used | Two-stage compression with intercooler and aftercooler to manage heat |

| Maintenance | Requires regular oil and filter changes; higher maintenance complexity | No oil-related maintenance; simpler maintenance but higher initial cost |

| Initial Cost | Lower initial investment | Higher upfront cost due to specialized materials and design |

| Typical Applications | Heavy industry, general manufacturing where trace oil contamination is acceptable | Medical, pharmaceutical, food & beverage, electronics requiring ultra-clean air |

| Risk of Contamination | Possible oil carry-over despite filtration; risk of product or equipment damage | Eliminates oil contamination risk, critical for sensitive processes |

Oil-injected compressors offer reliable performance and lower initial costs, but require regular oil and filter maintenance.

Oil-Free

Oil-free rotary screw compressors avoid oil in the compression chamber. They use non-contacting rotors, special coatings, or water injection to ensure the compressed air remains free of oil contamination. These models achieve ISO Class 0 air purity, making them essential for industries like medical, pharmaceutical, food and beverage, and electronics. Oil-free compressors reduce the risk of product contamination and environmental impact, though they come with higher upfront costs.

- Food and beverage plants use oil-free compressors for packaging and cleaning.

- Pharmaceutical and chemical industries require high-purity air for process safety.

- Electronics and textile manufacturing depend on oil-free air to protect products.

Fixed Speed

A fixed speed rotary screw compressor operates at a constant speed. The motor runs continuously, drawing air through an intake filter and compressing it with intermeshed rotors. This design delivers a steady, uninterrupted airflow, making it ideal for applications that demand a constant supply of compressed air. Fixed speed models excel in 24/7 production environments, such as large factories, where reliability and full-duty operation are critical.

- The compressor draws air through a filter.

- Rotors compress the air at a constant speed.

- Compressed air exits through an aftercooler for moisture removal.

- The system runs at full power, providing consistent output.

Variable Speed

Variable speed rotary screw compressors use advanced drives to adjust motor speed based on real-time air demand. This technology reduces energy consumption by 25% to 70% compared to fixed speed models. The compressor only uses the power needed, which lowers operating costs and carbon emissions. Variable speed models also provide tighter pressure control and quieter operation, making them suitable for facilities with fluctuating air requirements.

Variable speed compressors offer significant energy savings and improved efficiency, especially in environments where air demand changes throughout the day.

Portable rotary screw compressors are also available. These units provide flexibility for construction sites, remote locations, and temporary industrial setups, delivering reliable compressed air wherever needed.

Advantages

Efficiency

A rotary screw compressor delivers high efficiency in demanding environments. Its design allows continuous airflow without pulsation, which ensures steady pressure and reduces energy waste. Unlike piston compressors, it produces air throughout the entire cycle, resulting in higher cubic feet per minute (CFM) per horsepower. Variable speed models further improve efficiency by adjusting power consumption to match air demand, minimizing unnecessary energy use. Over time, rotary screw compressors prove more cost-effective due to lower maintenance needs and operational savings.

| Efficiency Metric | Rotary Screw Compressors | Reciprocating (Piston) Compressors |

|---|---|---|

| Airflow Efficiency (CFM/HP) | Higher CFM per horsepower due to continuous air delivery | Lower, air produced only during half of the cycle |

| Moving Parts | Fewer moving parts, less friction loss | More moving parts, higher friction and energy loss |

| Internal Leakage | Lower internal leakage | Higher leakage due to piston and ring wear |

| Pressure Band | Tighter pressure control, especially with VSD (+/-1.5 PSIG) | Wider pressure fluctuations (+/-10-30 PSIG) |

Rotary screw compressors operate continuously, providing smooth and reliable airflow for high-demand applications.

Reliability

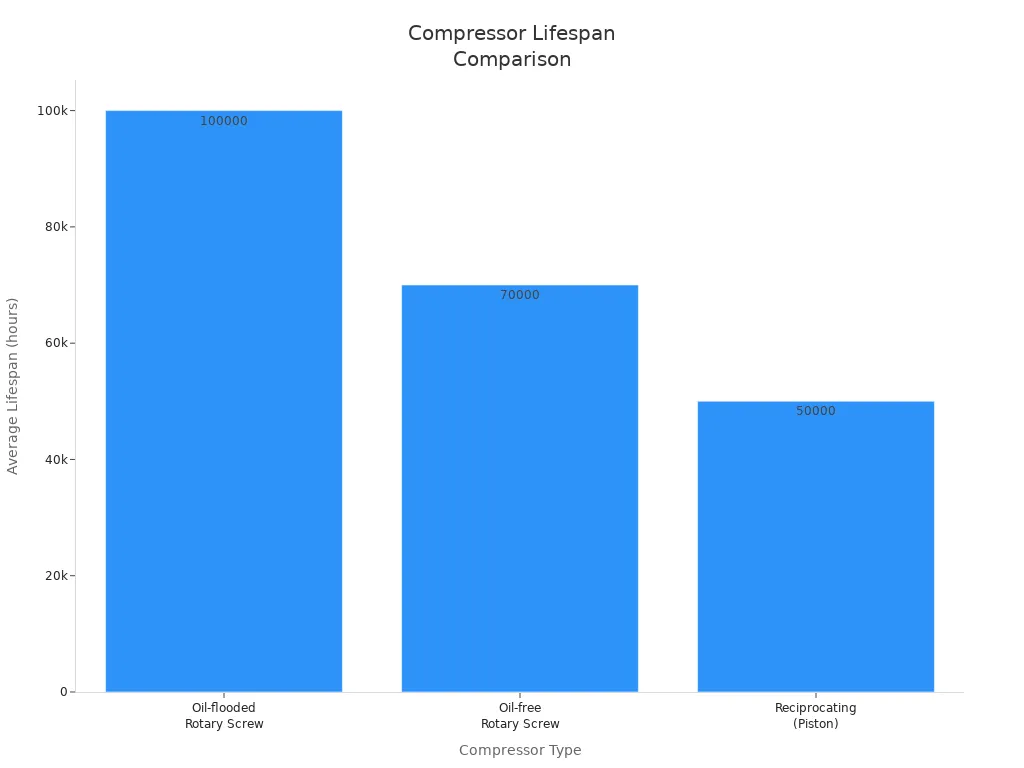

Rotary screw compressors are built for continuous operation. Many models run 24/7 in industrial settings, demonstrating exceptional reliability. With fewer moving parts, these compressors experience less wear and tear, which extends their lifespan. Oil-flooded rotary screw compressors can last up to 100,000 hours with proper maintenance. Regular practices such as changing lubricants, replacing filters, and inspecting for leaks help maintain peak performance and prevent breakdowns.

Industrial Applications

Rotary screw compressors serve a wide range of industries. Manufacturing plants use them to power production equipment, conveyors, and packaging lines. In the food and beverage sector, they support air-jet processing, drying, and packaging. Agriculture relies on these compressors for grain transport, spraying, and greenhouse ventilation. Oil and gas operations use them for drilling, gas compression, and pneumatic transport. Their ability to deliver continuous, clean air makes them essential in process industries and other high-demand environments.

Comparison to Reciprocating

Rotary screw compressors outperform reciprocating compressors in several key areas. They provide continuous air output, quieter operation, and longer service life. Reciprocating compressors, while less expensive initially, require more frequent maintenance and have shorter lifespans. Rotary screw compressors excel in large-scale, high-volume, and continuous-use scenarios, making them the preferred choice for most industrial applications.

Why Choose Sollant

China Factory Strength

Sollant stands out as a leading manufacturer in China, recognized for its robust production capabilities and strict quality control. The factory produces approximately 600 units each month, resulting in an annual output of about 7,200 compressors. This high capacity ensures timely delivery for both domestic and international clients.

Sollant’s commitment to quality is evident in its certifications and inspection processes.

- The factory holds ISO9001:2000 certification, obtained in 2007.

- CE certification demonstrates compliance with European safety standards.

- Every compressor undergoes calibration before shipment.

- Quality inspection reports accompany all outgoing products.

- The facility welcomes third-party inspections for added transparency.

- Each generator set receives two thorough checks before leaving the factory.

These measures guarantee that every product meets strict performance and safety standards. Sollant’s dedication to quality management builds trust with customers worldwide.

Product Range

Sollant offers a comprehensive range of compressors designed to meet diverse industrial needs. The company’s product lineup includes oil-injected and oil-free models, as well as fixed and variable speed options. Customers can select from standard units or request custom solutions for unique applications.

Key features that set Sollant apart from other brands include:

- Internationally recognized third-generation asymmetric twin-screw air ends for high efficiency.

- Large fan and advanced heat exchanger designs for superior cooling.

- Adjustable pressure settings from 7 to 12 bar.

- Energy savings of 30-40% on electricity costs.

- High-performance permanent magnet synchronous motors with a service life of up to 15 years.

- Advanced filtration technology for cleaner air output.

- Reliable operation in extreme weather conditions.

- Competitive pricing and strong after-sales support.

Sollant’s focus on innovation, reliability, and customer satisfaction makes it a preferred source for industrial air solutions.

A rotary screw compressor delivers reliable, efficient, and quiet compressed air for industrial applications. Its design ensures steady airflow, low maintenance, and long-term cost savings. Key benefits include:

- High energy efficiency and reduced operational costs

- Consistent output and low noise levels

- Versatility across industries

Selecting the right compressor involves evaluating power needs, usage frequency, environmental conditions, and air purity requirements. Sollant provides dependable solutions tailored to diverse industrial demands.

FAQ

What maintenance does a rotary screw compressor require?

Operators should check and replace air and oil filters regularly. They must monitor oil levels, inspect belts, and clean coolers. Routine maintenance prevents breakdowns and extends equipment life.

How long does a rotary screw compressor typically last?

A well-maintained rotary screw compressor often operates for 60,000 to 100,000 hours. Proper servicing and timely part replacement help maximize lifespan.

Can a rotary screw compressor run continuously?

Yes. Rotary screw compressors support continuous operation. Their design allows them to deliver steady airflow without overheating, making them ideal for demanding industrial environments.

What industries use rotary screw compressors most?

Manufacturing, food and beverage, pharmaceuticals, automotive, and oil and gas industries rely on rotary screw compressors. These sectors need consistent, high-quality compressed air for critical processes.

How does a rotary screw compressor differ from a piston compressor?

A rotary screw compressor provides continuous, quiet airflow with fewer moving parts. Piston compressors operate in cycles, create more noise, and require more frequent maintenance.