What Is a Dryer Compressor and How Does It Work

A dryer compressor takes water out of compressed air. This keeps your equipment safe. It also makes sure your air supply is clean. Dry air helps tools and machines work well. This is very important when you use a screw-air-compressor-air-dryer. If you know how a dryer works, you can stop rust. You can also avoid damage and expensive repairs.

Table of Contents

Key Takeaways

A dryer compressor takes water out of compressed air. This keeps your tools safe and stops rust from forming.

If you take care of your dryer compressor, you can save money. It also helps your equipment last longer.

You need to pick the right dryer compressor for your needs. Some types are refrigerated or desiccant.

You should check the dew point in your air system often. This helps stop water from building up and keeps things working well.

Clean, dry air makes products better and safer. This is very important for food and electronics industries.

Dryer Compressor Basics

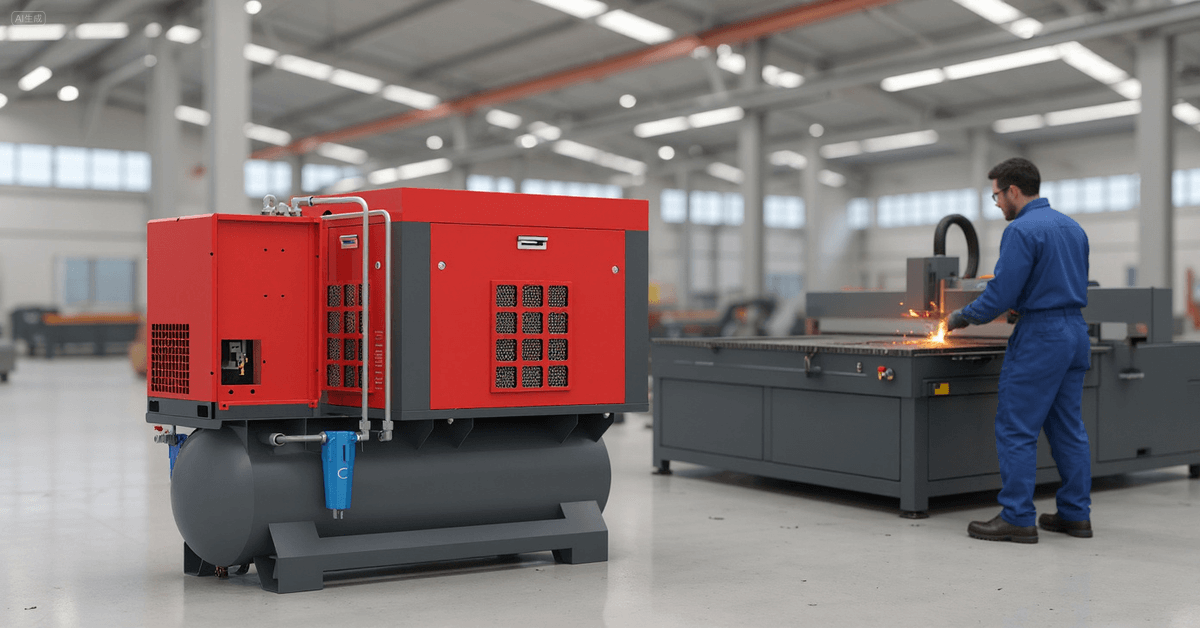

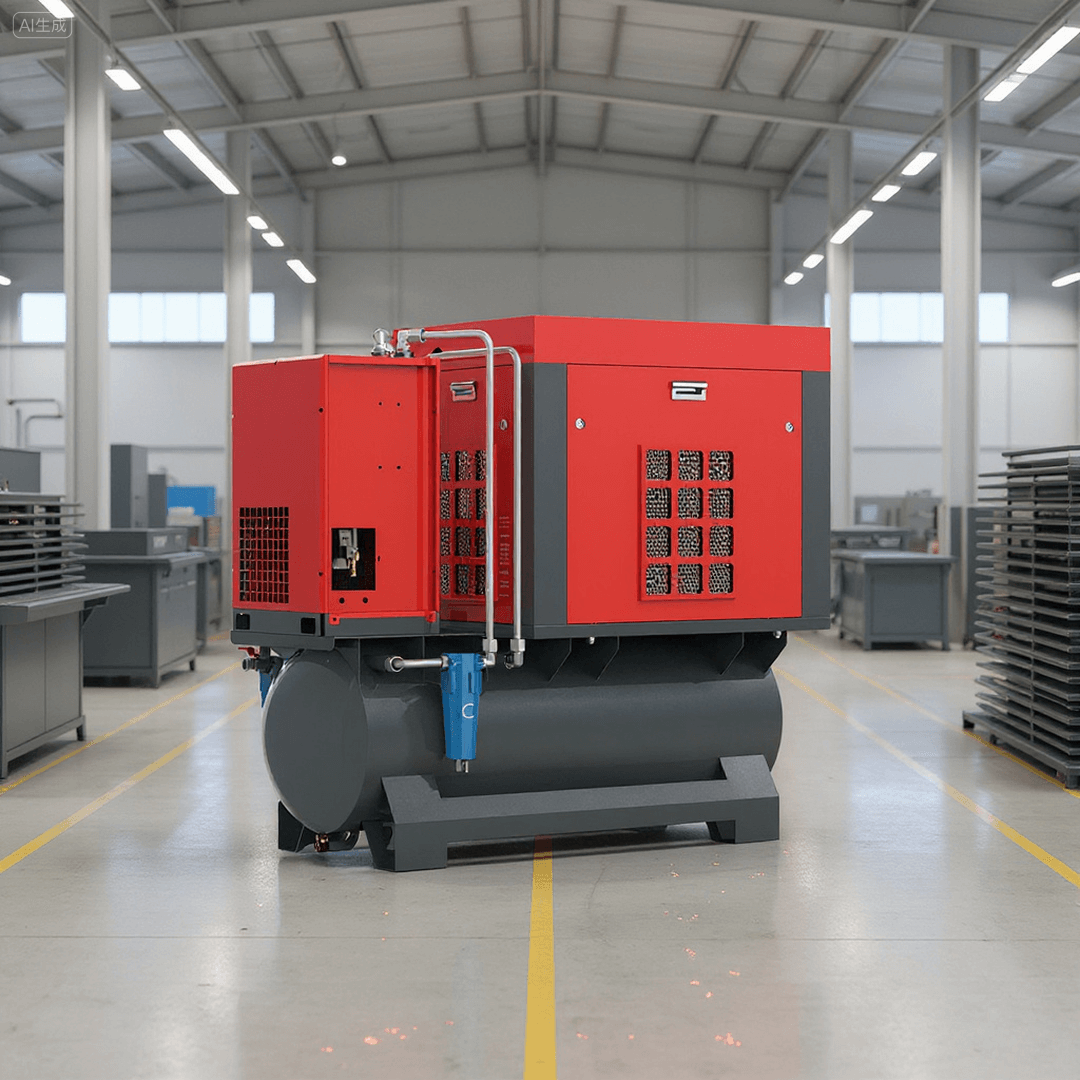

What It Is

A dryer compressor gives you dry air for your machines. It takes water out of compressed air before it goes to your tools. This keeps everything safe and working well. Brands like sollant make these machines for many jobs. You can see dryer compressors in shops, factories, and places that need clean air.

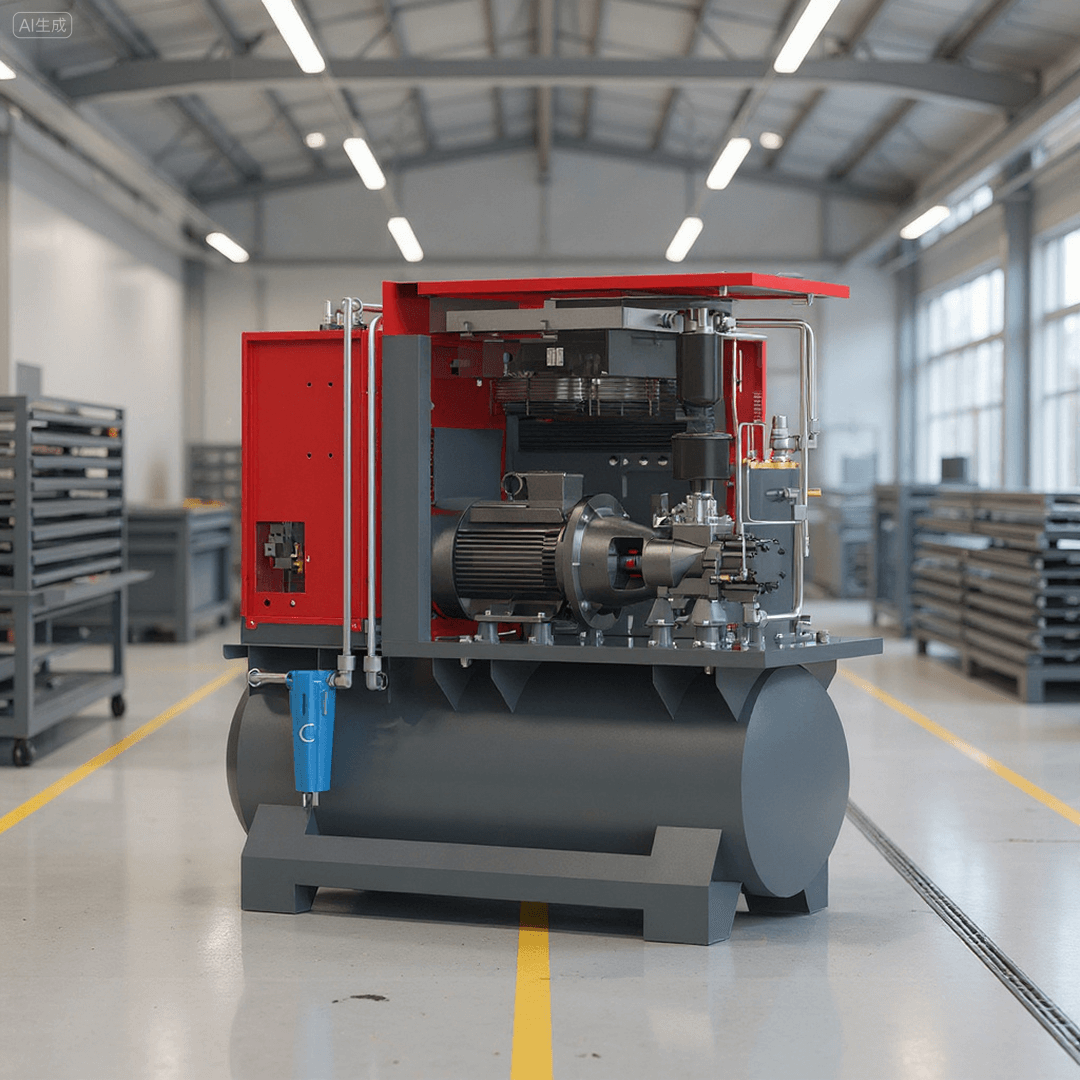

A dryer compressor system has many main parts:

Compressor: Makes air at the right pressure.

Air cooler: Cools the air so it does not get too hot.

Wet air receiver tank: Holds air for when you need extra.

Pre-filter: Stops dirt and dust before air goes to the dryer.

Dryer: Removes water from the compressed air.

After-filter: Cleans out any leftover dirt after the dryer.

Dry air tank: Stores the dry, clean air.

Condensate trap: Gets rid of water that builds up.

Distribution system: Sends dry air to your tools and machines.

You might wonder how a dryer compressor is not the same as a regular air compressor. A normal air compressor only makes air with more pressure. A dryer compressor also takes out water, so your air stays dry and safe.

Why It Matters

You need a dryer compressor to keep your machines safe and working. If you do not use a dryer, water builds up inside your system. This can cause rust and damage. Water can hurt pipes and tanks. Your tools might stop or get stuck, which means more repairs and higher costs.

Water in compressed air can block pipes, break seals, and change pressure. It can also bring in germs and dirt, which can hurt products and cause health problems in food or paint work.

When water mixes with dirt, it makes thick sludge. This sludge can block pipes and valves, so your system does not work well. You might need to use more pressure to keep things running, which uses more energy and costs more money.

If you ignore water, you will spend more time and money fixing things. Oil stops working, and parts wear out faster. You might have to stop work and lose time.

Here is a quick list of problems water can cause:

Problem | Effect on Equipment |

|---|---|

Corrosion | Rust, blocked pipes, dirty air |

Damage to components | Broken seals, pressure changes |

Contamination | Health risks, bad product quality |

Increased costs | More repairs, downtime, waste |

A dryer compressor helps you stop these problems. You get clean, dry air for your machines. You save money and keep your work safe. Sollant and other brands have options for you, so your air system works well.

How Dryer Compressors Work

Compression and Moisture Removal

A dryer compressor starts with air from outside. This air has water vapor in it. The compressor pulls in the air and squeezes it. Squeezing the air makes it hotter. Hot air can hold more water vapor. You must take out this moisture before it goes to your tools.

Here is how the process works:

Cooling Plus Separation: The dryer cools the squeezed air. Cooling turns water vapor into tiny drops. The system takes these drops out of the air.

Over Compression: The compressor pushes the air to high pressure. When the air expands, it lets out more moisture. The dryer removes this extra moisture.

Membrane Drying: Some dryers use special membranes. These membranes let water vapor go through. Dry air stays inside.

Absorption Drying: Some dryers use chemicals. These chemicals soak up water vapor from the air.

Adsorption Drying: Other dryers use special materials. These materials grab and hold water vapor. They pull it out of the air.

You can find these ways in sollant dryer compressors. Each way helps you get dry, clean air for your machines.

Tip: Taking out moisture from compressed air keeps your equipment safe. It helps your system work well.

Dew Point and Air Quality

You need to watch the dew point in your air system. The dew point is when water vapor turns into liquid. If the air gets colder than this, water forms. Water can hurt your equipment.

Lowering the dew point stops water from forming in pipes and tools. This keeps rust and blockages away. Your air stays clean and dry. Keeping the dew point right is important for food, paint, and electronics jobs. Moisture can ruin products and cost you money.

Here are some facts about dew point and air quality:

Lower dew point means less water in your system.

You stop rust and corrosion by keeping dew point low.

Clean, dry air keeps your tools safe and makes products better.

Good dew point control helps you follow rules in special jobs.

Check the table for dew point levels for different dryers:

Type of Air Dryer | Dew Point Range (°C) | Dew Point Range (°F) | Applications |

|---|---|---|---|

Membrane Air Dryers | -20 to -40 | -4 to -40 | Moderate moisture removal, energy efficiency |

Refrigerated Air Dryers | 3 to 10 | 37 to 50 | General industrial applications |

Desiccant Air Dryers | -40 to -70 | -40 to -94 | Food and beverage, pharmaceutical manufacturing, electronics production |

If you work in a regular shop, you may need a dew point near 50°F. Paint and food jobs need lower dew points, sometimes down to -40°F. Medicine making may need even lower, close to -100°F.

Note: Sollant has dryer compressors with good dew point control. You can pick the right dryer for your job and keep your air system safe.

Types of Dryer Compressors

You need to know the main types of dryer compressors. Each type removes moisture in its own way. Brands like sollant have choices for every job.

Refrigerated Air Dryer

A refrigerated air dryer cools air to take out water. You see these dryers in many shops and factories. The dryer compressor pushes air into the system. The refrigerated air dryer makes the air colder. Water vapor turns into drops. The system takes out these drops and sends dry air.

Here is what happens in a refrigerated air dryer:

Pre-cooling

Heat exchange

Deep cooling

Moisture condensation

Gas-liquid separation

This dryer works well in high humidity. It is best when you need a dew point from 37°F to 50°F. You use it for most industrial jobs.

Membrane Dryer

A membrane dryer uses special fibers to separate water vapor. Air goes through the membrane. Water vapor leaves, and dry air stays inside. There are no moving parts. Maintenance is easy if you keep the membrane clean.

You use a membrane dryer for energy savings and moderate moisture removal. Sollant has membrane dryers for small shops and labs.

Tip: Membrane dryers last longer if you keep out dust and oil.

Desiccant Dryer

A desiccant dryer uses adsorbent materials to grab water vapor. Air flows through a bed of desiccant. The material holds the water. When the bed is full, the system switches to another tower and cleans the first one.

You pick a desiccant dryer when you need very dry air. This dryer can reach dew points as low as -94°F. You see desiccant dryers in food, medicine, and electronics work.

Comparison Table

Feature | Refrigerated Air Dryer | Desiccant Dryer |

|---|---|---|

Moisture Removal Method | Cools air to make water drops, then separates them. | Uses adsorbent materials to grab water, then releases it during cleaning. |

Process Stages | Has pre-cooling, heat exchange, deep cooling, moisture condensation, and separation. | Has adsorption, checks for saturation, cleans, and switches between two towers. |

Efficiency | Works well in high humidity but only at certain temperatures. | Works in low humidity and gets lower dew points, but uses more energy. |

Each dryer type removes moisture in a different way. Refrigerated air dryers use cooling. Membrane dryers use fibers. Desiccant dryers use adsorbent materials. You choose the dryer compressor that fits your needs and the air quality you want.

Pros and Cons

Refrigerated Air Dryer

A refrigerated air dryer helps your machines by giving dry air. Sollant makes models for shops and factories. There are good things and some not-so-good things about this dryer.

Advantages:

It takes out water and gives you dry air.

It stops rust and keeps pipes safe.

You spend less money fixing things.

It meets rules for clean, dry air.

Your work gets faster and better.

New designs use less energy.

Disadvantages:

It works best where the weather is not too hot or cold.

You need to clean it often so it stays cool.

It may not work for jobs needing very dry air.

Note: These dryers use safe refrigerants and help the environment.

Membrane Dryer

A membrane dryer helps control moisture in your air. It is easy to take care of and saves energy.

Pros:

There are no moving parts, so it lasts longer.

It is quiet, good for labs and small shops.

It saves energy and removes some moisture.

It is small and fits in tight places.

Cons:

You need clean air to keep the membrane safe.

It may not work with lots of air or very wet air.

It costs more at first than other dryers.

Tip: Clean your membrane dryer often so it works well.

Desiccant Dryer

Pick a desiccant dryer if you need very dry air. Sollant has these dryers for food, medicine, and electronics.

Pros:

It can make air very dry for special jobs.

It works in places with lots of moisture.

It works well when it is cold outside.

Cons:

It uses more energy, especially heatless types.

Heated types use more power but save air.

Blower purged types cost more but use less air.

You need to check and change the desiccant often.

Dryer Type | Best For | Energy Use | Maintenance Needs |

|---|---|---|---|

Refrigerated | General industry | Moderate | Low |

Membrane | Labs, small shops | Low | Low |

Desiccant | Food, pharma, electronics | High (heatless) | Medium to High |

You can choose the best dryer compressor by thinking about your air needs and how much energy you want to use.

Maintenance Tips

Routine Checks

You should check your dryer often. Look at the control panel for problems. Watch for warning lights or faults. Check the air temperature. It must be under 100 degrees F. The pressure should be at least 100 psi. Make sure the room is not too hot. Keep it below 100 degrees F. Inspect the aftercooler and clean it. Test the automatic drain to see if it works. For refrigerated dryers, watch the heat exchanger and refrigerant pressure. If you use a membrane dryer, check prefilters for blockages. For desiccant dryers, watch the dew point. Check the dust filter for pressure drops.

Tip: Checking your dryer often helps you find problems early. This keeps your sollant dryer working well.

Cleaning and Replacement

Clean parts often to keep your air safe. Change pre-filters, afterfilters, and point-of-use filters every 6-12 months. You can also change them after 2000-4000 hours of use. If you see a pressure drop, change filters sooner. Check the drain valve once a year. Make sure it removes water. Watch coalescing filters and change cartridges when needed. For desiccant dryers, check the desiccant for size and color. Replace it if it looks dirty or worn.

Component | Cleaning Frequency | Replacement Interval |

|---|---|---|

Filters | Every 6-12 months | 2000-4000 hours |

Drain Valve | Annually | As needed |

Desiccant | Sample periodically | Replace if contaminated |

Troubleshooting

If your dryer has problems, check the control panel first. Look for error codes. Make sure air temperature and pressure are safe. Check for blockages in filters and drains. If you see water in air lines, the drain may not work. The filter could be clogged. For desiccant dryers, a high dew point means you need new desiccant. If you hear strange sounds or see leaks, call a sollant technician.

Regular care helps your dryer use less energy. You can avoid expensive repairs.

You need a dryer compressor to keep your air system safe. Sollant has choices for every kind of job. When you pick a dryer compressor, follow these steps. First, check how much air you need. Next, look at the air quality and your work area. Pick a model that saves energy. Choose equipment that is easy to take care of. Think about the price and how long it will last.

Benefit | Description |

|---|---|

Energy Savings | |

Extended Equipment Life | Regular checks help your compressor work longer. |

Reduced Repair Costs | Fixing problems early costs less than big repairs. |

Increased Productivity | Fewer problems mean you can keep working. |

Improved Air Quality | Clean air systems keep your products safe. |

Enhanced Safety | Checking your system helps keep your team safe. |

You should follow tips for taking care of your dryer. Use certified parts for repairs. Look for ISO 7183 and CE marks when you buy. If you have trouble, ask a sollant technician for help.

FAQ

What does a dryer compressor do for my air tools?

You get dry air for your tools. The dryer compressor removes water from the air. This keeps your equipment safe and helps your tools last longer.

How often should I check my dryer compressor?

You should check your dryer compressor every week. Look for warning lights and test the drain. Regular checks help you spot problems early.

Can I use a compressed air dryer in my workshop?

Yes, you can use a compressed air dryer in your workshop. Sollant offers models for small shops. You get clean, dry air for painting, cleaning, and running tools.

What happens if I skip dryer maintenance?

If you skip maintenance, water can build up. This causes rust, damage, and higher repair costs. You may lose time fixing your equipment.

How do I choose the right dryer compressor?

You should look at your air needs and workspace. Sollant has options for different jobs. Pick a model that matches your air quality and energy savings goals.