Specifications for daily management and use of screw air compressors

You play a vital role in maintaining screw air compressors in your facility. Consistent routines, such as scheduled maintenance and monitoring, boost reliability and efficiency. Industry studies show that following technical specifications and general rules and specifications leads to better energy efficiency and lower costs. Sollant, a trusted rotary screw compressor manufacturer, recommends focusing on five key areas: responsibilities, inspections, maintenance, safety, and troubleshooting. Accurate operation records help you optimise performance and control costs for your compressors.

Table of Contents

Key Takeaways

Establish clear management roles for screw air compressors. Assign specific tasks for routine maintenance, inspections, and safety checks to ensure smooth operation.

Conduct daily inspections to monitor key operating parameters. Regularly check oil levels, discharge pressure, and temperature to prevent unexpected failures.

Maintain accurate operation and maintenance records. Document inspections and repairs to track performance and identify recurring issues.

Follow a structured maintenance schedule. Perform daily, weekly, and monthly tasks to enhance efficiency and extend the lifespan of your compressors.

Ensure proper operator training. Equip your team with the necessary skills and knowledge to operate and maintain compressors safely and effectively.

Management Responsibilities

Equipment management roles

You need a clear structure for managing screw air compressors in your facility. Each role has specific tasks that keep your equipment running smoothly. The table below outlines the main responsibilities for equipment managers:

Responsibility Type | Description |

|---|---|

Routine Maintenance | Follow manufacturer schedules for daily and weekly checks, monthly inspections, and part replacements. |

Daily/Weekly Checks | Carry out visual and audio inspections, log key readings, and ensure proper ventilation. |

Periodic Maintenance Tasks | Use checklists for inspecting filters, checking belts, and logging temperatures. |

Lubrication and Oil Management | Monitor oil levels, change oil regularly, and replace oil filters as scheduled. |

Safety Device Checks | Test pressure relief valves and confirm sensors work correctly. |

Maintenance Logs | Record service dates, observations, and readings for traceability. |

Leak Checks | Include leak detection in your maintenance routine. |

Electrical Maintenance | Keep motors clean, monitor amp draw, and grease bearings as needed. |

Sollant supports you with technical training and detailed documentation, making it easier to follow these routines and maintain high standards.

Operator training and qualifications

You must ensure that every operator is properly trained before handling a screw air compressor. Operators should have:

Basic knowledge training: Learn about compressor parts, safety rules, and how to operate the machine.

Technical skills training: Gain skills in troubleshooting, basic maintenance, and improving performance.

Advanced training: Understand system design, energy management, and industry regulations.

Sollant offers training programmes to help your team reach these standards, ensuring safe and efficient operation.

Maintenance personnel duties

Maintenance staff play a vital role in keeping your compressors reliable. Their main duties include:

Inspect air filters regularly and replace them when needed.

Test system controls and monitor safety readings.

Check oil filters and oil levels daily to prevent wear.

Inspect rotor compression and adjust tension for best performance.

Follow routine maintenance schedules, including weekly and annual checks.

Sollant’s after-sales support and technical resources help your maintenance team stay up to date with best practices. This approach ensures your equipment remains efficient and safe throughout its service life.

Daily Inspections for Screw Air Compressors

Daily inspections help you maintain the reliability and efficiency of screw air compressors. You can prevent unexpected failures and costly downtime by following a standardised routine. Early detection and prompt reporting of abnormalities are essential for safe and economical operation.

Monitoring operating parameters

You should monitor key operating parameters every day. Recording these values hourly allows you to spot trends and identify issues before they become serious. The table below shows the most important parameters to check:

Description | |

|---|---|

Oil Level | Ensure the oil level in the oil-gas separator is above the minimum mark. |

Discharge Pressure | Monitor the pressure at which the air is discharged from the compressor. |

Discharge Temperature | Check the temperature of the air being discharged to prevent overheating. |

Voltage | Record the voltage supplied to the compressor for stability checks. |

Current | Monitor the current draw to ensure it is within normal operating limits. |

Abnormalities | Stop the compressor if there are abnormal vibrations, noises, or oil leaks. |

Tip: You should always stop the machine if you notice abnormal vibrations, noises, or oil leaks. Early action prevents further damage and keeps your equipment safe.

Equipment condition checks

You need to inspect the physical condition of screw air compressors regularly. These checks help you find leaks, wear, and other problems before they affect performance. Leading manufacturers recommend the following inspection routines:

Drain the drip tray daily to prevent moisture buildup.

Monitor the compressor’s temperature to avoid overheating.

Check for rust and signs of corrosion.

Ensure adequate lubrication to reduce friction and heat.

Monitor for excessive pressure and adjust as necessary.

Inspect for leaks (air, moisture, and oil).

Verify proper operation of controls and indicators.

Check the air filter for blockages.

Observe for unusual noise or vibration.

Examine safety relief valves for signs of activation or tampering.

Inspect hoses and connections for wear or damage.

Review operating pressure levels.

Check condensate traps.

Look for noticeable signs of damage.

You should perform these checks daily, weekly, and monthly, as shown in the table below:

Frequency | |

|---|---|

Daily | Inspect for air/oil leaks, top off oil, drain condensate, check noise/vibration. |

Weekly | Clean/change inlet filters, test controls. |

Monthly | Clean heat exchangers; check belts and hoses. |

Basic PM | 1,000–2,000 hrs/6 months: Change filters, log conditions, tighten connections. |

Full PM | 2,000–4,000 hrs/12 months: Add oil separators, replace belts and drain valves. |

Triennial PM | 8,000–12,000 hrs/3 years: Rebuild valves, replace thermal/solenoid valves, drive coupling, and starter contacts. |

Note: Consistent inspections help you catch problems early. You can avoid expensive repairs and keep your compressor running smoothly.

Instrument accuracy

Accurate readings are vital for effective monitoring. You must verify the accuracy of pressure gauges, thermometers, and other instruments. Use these methods to ensure reliable measurements:

Account for measurement uncertainty when checking readings.

Identify and correct systematic errors to avoid incorrect efficiency assessments.

Maintain and install sensors properly for long-term stability.

Follow specific installation requirements for each instrument to improve accuracy.

You should calibrate instruments at least once a year. Proper calibration helps you trust your readings and make informed decisions about maintenance and operation.

Tip: Regular calibration and maintenance of instruments protect you from unexpected failures and help you maintain optimal performance.

Maintenance for Industrial Air Compressor

Proper maintenance is the foundation of reliable industrial air compressor operation. You can achieve high efficiency, reduce downtime, and extend equipment life by following a structured compressor maintenance schedule. This section explains the essential routines and intervals for rotary screw compressor care, helping you meet technical specifications and general rules and specifications in your facility.

Daily and weekly routines

You should perform daily maintenance and weekly checks to keep your industrial air compressor in optimal condition. These routines help you detect issues early and maintain efficiency. The following table summarises the most important daily and weekly tasks:

Interval | Tasks |

|---|---|

Daily | Inspect for air/oil leaks, top off oil, drain condensate, check noise/vibration. |

Daily | Check oil level, inspect for unusual noises or vibration, drain water from air receiver tank. |

Daily | Check oil, drain condensate, inspect gauges. |

Weekly | Clean/change inlet filters, test controls. |

Weekly | Clean air filter; replace if necessary, wipe down air compressor system exterior. |

Weekly | Inspect filters, belts, couplings, safety valves. |

You should always check the oil level and drain condensate from the air receiver tank every day. Listen for unusual noises and vibrations. These signs often indicate problems that affect efficiency. Each week, clean or replace the air filter and inspect belts, couplings, and safety valves. Wipe down the compressor exterior to prevent dust buildup. These steps form the backbone of routine maintenance and support long-term reliability.

Tip: Consistent daily and weekly routines help you avoid unexpected breakdowns and keep your rotary screw compressor running at peak efficiency.

Monthly and annual servicing

Monthly and annual servicing ensures your industrial air compressor meets technical specifications and maintains high efficiency. You should follow a strict compressor maintenance schedule based on operating conditions and maintenance cycles. The table below outlines standard intervals for servicing:

Compressor Type | Recommended Service Interval |

|---|---|

Oil-flooded rotary screw | |

Reciprocating | Every 1,000 hours or every six months |

Most industrial air compressor systems require servicing at least once a year. If you use your compressors more frequently, you may need to service them quarterly or even monthly. During monthly checks, inspect the quality of lubricating oil and replace it if it appears dark or contaminated. Test the sensitivity of safety valves and pressure switches. Clean the coolers to improve heat dissipation. Annually, you should perform a comprehensive inspection of the main engine, check rotor clearance, and calibrate all measuring instruments.

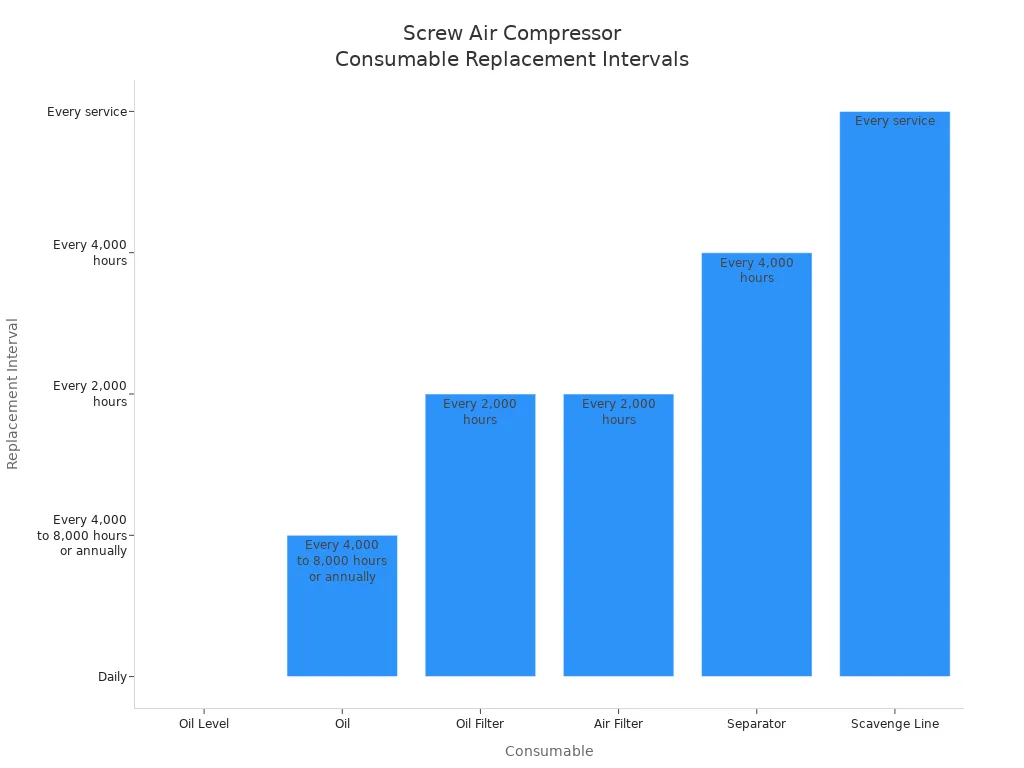

You must also focus on the regular replacement of consumables. The following table shows recommended intervals for key components:

Consumable | Replacement Interval |

|---|---|

Oil Level | Daily |

Oil | |

Oil Filter | Every 2,000 hours |

Air Filter | Every 2,000 hours |

Separator | Every 4,000 hours |

Scavenge Line | Every service |

You should always follow the compressor maintenance schedule for regular replacement of consumables. This practice supports efficiency and prevents costly repairs.

Note: Timely replacement of filters, oil, and separators is essential for maintaining technical specifications and energy efficiency.

Sollant maintenance support

Sollant provides comprehensive support for industrial air compressor maintenance. You benefit from detailed technical specifications, after-sales service, and guidance on routine maintenance. Sollant recommends replacing the oil filter after the first 500 hours of operation, then every 1,500 to 2,000 hours. The oil fine separator should be replaced after about 3,000 hours, depending on the quality of lubricating oil and air filtration. Regular cleaning of the cooler with compressed air ensures proper heat dissipation and supports efficiency.

Sollant’s technical team helps you design a compressor maintenance schedule tailored to your operating conditions and maintenance cycles. You receive reminders for regular replacement of consumables and access to high-quality spare parts. Sollant’s advanced design and robust components ensure your rotary screw compressor meets demanding technical specifications and delivers consistent efficiency.

Tip: Sollant’s after-sales support and technical resources help you maintain your industrial air compressor at the highest standards, ensuring long-term reliability and energy efficiency.

Safe Operation of Rotary Screw Compressor

Safe operation is essential for maintaining the reliability and efficiency of rotary screw compressors. Following general rules and specifications helps you protect both equipment and personnel. You should always follow a standard procedure for starting, running, and shutting down your compressor.

Pre-startup checks

Before you start the compressor, carry out these checks to ensure safe operation:

Inspect all mechanical parts and pipes for reliability.

Verify the oil level is within the recommended range.

Manually turn the coupling to check for smooth rotation.

Confirm that all electrical requirements are met.

Ensure all guards are in place and fastened securely.

Check that hoses and pipes are in good condition and secure.

Make sure there are no leaks or loose fasteners.

Confirm that safety valves and pressure relief devices are not blocked.

Check that air filters are clean and not clogged.

Tip: Always keep a record of your pre-startup checks. Analysing these records helps you spot trends and improve energy efficiency.

Operation precautions

When running the compressor, you must follow these precautions to maintain safety and efficiency:

Never remove or tamper with sound-damping materials or safety devices.

Monitor operating parameters such as exhaust pressure and temperature.

Check for oil or air leaks during operation and stop the machine if you find any.

Ensure all electrical leads are secure and in good order.

Do not allow cooling air filters to become clogged.

Take steps to prevent air pollution if you use warm cooling air for heating.

Implement measures to avoid harmful bacteria growth in water-cooled compressors.

Note: Wearing personal protective equipment, such as gloves and safety glasses, is a must when working with compressors.

Shutdown and emergency procedures

You need to follow a clear process when shutting down the compressor or responding to emergencies:

For normal shutdown, close the air inlet valve and let the compressor run without load for several minutes.

Switch off the power supply once the temperature drops below 60°C.

In an emergency, press the emergency stop button immediately if you notice:

Excessive current or pressure readings

Interrupted cooling water supply (for water-cooled units)

High oil or water temperature

Abnormal noises or strong vibrations

Severe gas leaks or burning smells

After shutdown, release any remaining gas to reduce pressure to zero.

Drain condensed water from the relevant components.

Record the time, type, and cause of any emergency shutdown for future maintenance.

Callout: Quick action during emergencies protects both your equipment and your team. Always document incidents to support future improvements in safety and efficiency.

Troubleshooting Screw Air Compressors

Fault logging

You should keep accurate operation and maintenance records for your screw air compressors. These records help you track faults and identify patterns over time. When a fault occurs, log the date, time, symptoms, and actions taken. This information allows you to analyse recurring issues and improve your troubleshooting process. Detailed logs also support warranty claims and help you communicate clearly with technical support teams, such as those at Sollant.

Tip: Consistent record-keeping makes it easier to spot trends and prevent future breakdowns.

Common issues and solutions

Screw air compressors can develop several common faults. You can solve many of these problems by following standard procedures. The table below lists frequent issues, their causes, and recommended solutions:

Fault Type | Causes | Solutions |

|---|---|---|

Slide valve not at zero, excess oil, low voltage | Reset slide valve, drain oil, check voltage | |

Operational Faults | Incorrect settings, control circuit failure | Adjust settings, repair circuits |

Abnormal Vibrations | Loose bolts, misalignment, pipeline vibration | Tighten bolts, realign, stabilise pipelines |

If you notice high temperature, check the cooling system and oil levels. For low pressure, inspect filters and valves. Excessive noise often points to worn bearings or loose parts. Sollant offers advanced parts and technical support to help you resolve these faults quickly and maintain high efficiency.

Preventive measures

You can reduce the frequency of faults by following a few simple preventive steps. Regular maintenance keeps your compressors running smoothly and supports energy efficiency. The table below shows key preventive measures:

Preventive Measure |

|---|

Change oil and filters |

Check and adjust belts and pulleys |

Clean compressor housing |

Inspect and clean coolers |

By following these steps, you extend the life of your equipment and avoid costly repairs. Sollant’s technical team can guide you in setting up a maintenance plan tailored to your needs.

Note: Preventive care is the best way to ensure reliable operation and long-term savings.

Accurate Operation and Maintenance Records

Keeping accurate operation and maintenance records is essential for the long-term reliability of your screw air compressors. You can use these records to track performance, plan maintenance, and prevent unexpected breakdowns.

Daily logs and documentation

You should document every inspection, test, and maintenance activity. This habit helps you spot patterns and address issues before they become serious. Use a daily log to record key details such as operating hours, oil levels, and any faults you notice. The table below shows best practices for maintaining daily logs:

Best Practice | Description |

|---|---|

Document Inspections and Tests | Record all inspections, tests, and replacements, including data on operating conditions. |

Conduct Daily Equipment Checks | Regular checks help prevent larger issues and ensure optimal operation. |

Review Maintenance Logs | Check logs regularly to identify recurring issues and plan for future maintenance. |

Tip: Consistent documentation makes it easier to communicate with your maintenance team and technical support.

Performance tracking

You can improve efficiency by tracking performance metrics over time. Recording data such as pressure, temperature, and running hours allows you to see how your compressor performs under different conditions. Advanced tracking methods, like machine learning, can predict performance and help you optimise your system. When you monitor these metrics, you make better decisions about maintenance and upgrades, which leads to cost savings and improved reliability.

Sollant recommended practices

Sollant recommends that you create a comprehensive file for each compressor. Include the purchase date, model, configuration, and operating hours. Record every maintenance visit, noting which parts you replaced and which lubricants you used. Document the time and symptoms of any faults, along with the steps you took to fix them. Keep detailed records of troubleshooting processes and solutions. These accurate operation and maintenance records help you plan future maintenance and support warranty claims.

Note: Sollant provides templates and support resources to help you maintain detailed records and keep your compressors running smoothly.

Manufacturer Instructions and Support

User manual compliance

You should always read the user manual before operating a rotary screw compressor. The manual explains how to install, start, and maintain your equipment. You will find important safety instructions and technical details in the user manual. Manufacturers recommend that you:

Change air compressor filters every 2,000 hours, or more often if your environment is dusty.

Drain water from the compressor daily. Automated drain valves can help you save time.

Install the compressor in a space with good ventilation and a stable power supply.

Check the distribution system, air quality, and noise levels.

Follow all safety steps in the manual to protect yourself and your equipment.

The user manual also lists regular inspection tasks. You should drain excess water, check and change oil, replace filters, and inspect all components as described in the manual. If you follow the user manual, you will keep your compressor running safely and efficiently.

Tip: Keep your user manual in an easy-to-reach place. You may need to check the manual for troubleshooting or maintenance steps.

Updates and technical assistance

Manufacturers often update the manual to include new safety features or improved maintenance routines. You should check for updates on the official Sollant website. If you have questions about the manual or need help with installation, Sollant provides technical assistance. You can contact Sollant by email or phone for support. The technical team will help you understand the manual and solve any problems you face.

Visit https://www.sollant.biz/ for the latest manual updates.

Use the contact channels for quick answers to your questions.

Ask for guidance if you are unsure about any part of the manual.

Warranty and after-sales service

Sollant offers strong warranty and after-sales service for rotary screw compressors. You get access to genuine parts and free mechanical servicing during the warranty period. The table below shows the main features:

Feature | Details |

|---|---|

Warranty Duration | At least 1 year |

After-sales Support | Excellent customer support for setup and servicing |

Genuine Parts Availability | Supply of genuine rotary air compressor parts |

Free Mechanical Servicing | Included during warranty period |

Sollant’s warranty lasts up to 24 months. After-sales service helps you solve problems quickly and keeps your compressor in top condition. You can rely on Sollant for expert advice and fast delivery of genuine parts. Always use the manual and user manual to guide your maintenance and repairs.

Note: Good after-sales service and a clear manual help you avoid downtime and extend the life of your compressor.

You can achieve reliable performance from screw air compressors by following consistent routines and keeping accurate records. Regular inspections, maintenance, and adherence to manufacturer specifications help you improve efficiency and reduce costs. Over time, you will notice several benefits:

Maintenance logs allow you to track performance and plan future work.

Well-maintained compressors operate with higher energy efficiency and require fewer repairs.

Proper management extends equipment lifespan and supports workplace safety.

Consult Sollant’s resources for further guidance and enjoy the long-term advantages of correct compressor management.

FAQ

What is the ideal frequency for routine maintenance on screw air compressors?

You should perform daily checks and weekly cleaning. Replace filters and oil every 2,000 hours. Complete a full inspection annually. Sollant recommends following the user manual for your specific model.

How do you identify abnormal compressor sounds?

Listen for metallic friction, creaking, or vibration. These noises often signal wear or loose parts. Stop the machine and inspect immediately. Early detection helps prevent costly repairs.

Which records should you keep for optimal compressor management?

You need to log operating hours, maintenance dates, replaced parts, and fault details. Sollant provides templates to help you organise these records. Accurate logs support warranty claims and future planning.

What safety gear do you need when working with screw air compressors?

You must wear gloves, safety glasses, and a hard hat. Protective clothing shields you from hot surfaces and moving parts. Sollant recommends following all safety instructions in the user manual.