11 Most Common Screw Air Compressor Problems and How to Repair Them

You face these 11 common screw-air-compressor problems: won’t start, low pressure, excessive noise, overheating, oil leaks, high oil use, air leaks, moisture issues, pressure fluctuations, electrical faults, and frequent shutdowns. This guide provides step-by-step repair instructions to help you minimize downtime and save money.

Businesses can lose $500–$1,000 for every hour a rotary-screw-air-compressor sits idle. You protect productivity by acting quickly. Whether you handle air compressor maintenance screw air compressor tasks yourself or rely on professional support, regular care and trusted brands like Sollant prevent most issues.

Table of Contents

Key Takeaways

Regular inspections and timely repairs can prevent costly downtime for your screw air compressor.

Maintaining proper oil levels and using high-quality parts extend the life of your compressor and ensure efficient operation.

Identifying and fixing air leaks early can save energy and reduce operational costs.

Routine maintenance tasks, such as checking filters and monitoring pressure, help catch problems before they escalate.

For complex issues, don’t hesitate to contact professional support to ensure safe and effective repairs.

Won’t Start

Symptoms

You notice your screw air compressor refuses to start. The control panel displays no activity. The motor remains silent. You may see warning lights or error codes. Sometimes, the system pressure stays above the set start pressure, preventing activation. In other cases, the compressor sits idle because other units in your system meet the air demand. Electrical faults, such as broken couplings or misalignment, can also stop the compressor from starting.

Common warning signs include:

No response when pressing the start button

Unusual silence from the motor or control panel

Error codes or warning lights on the display

System pressure remains high, above the cut-in setting

Repair Steps

You can resolve most start-up issues by following a systematic approach. Begin with the electrical system. Check all connections for security and ensure the power supply meets the required voltage. Next, verify that the air pressure is below the compressor’s cut-in setting. Inspect the motor-compressor coupling for signs of breakage or misalignment. Examine the compressor for air leaks and mechanical damage.

Troubleshooting steps:

Inspect the electrical system for secure connections and adequate power.

Confirm the system pressure is below the compressor’s cut-in setting.

Check the motor-compressor coupling for damage or misalignment.

Look for air leaks and mechanical faults.

Review the control system for improper slide valve positioning or component wear.

Ensure oil levels are sufficient for lubrication and cooling.

Tip: Always disconnect the power supply before performing any repairs to prevent injury.

Table: Common Causes and Solutions

Common Causes | Solutions |

|---|---|

Improper slide valve positioning | Adjust the slide valve |

Component wear | Repair or replace damaged components |

Insufficient voltage | Ensure adequate voltage supply |

Pipeline vibrations | Optimize control systems |

Inadequate oil levels | Ensure sufficient lubrication and cooling |

Sollant Tips

Sollant recommends regular inspection of your compressor’s electrical and mechanical systems. Use high-quality parts to reduce the risk of start-up failures. Maintain proper oil levels and follow the manufacturer’s guidelines for slide valve adjustment. If you encounter persistent issues, contact Sollant’s technical support team for expert assistance. You can find more troubleshooting resources and maintenance guides on Sollant’s official website.

🛠️ Pro Tip: Routine checks and timely repairs keep your screw air compressor reliable and minimize downtime.

Low Pressure

Signs

You notice your screw air compressor struggles to maintain the required pressure. Tools and machinery operate sluggishly. Production slows down. The pressure gauge displays readings below your setpoint. You may hear the compressor running longer than usual, yet the air supply remains weak. Sometimes, warning lights or alarms indicate a pressure drop. Operators often report inconsistent performance or difficulty meeting air demand.

Common signs include:

Pressure gauge shows lower than expected readings

Extended compressor run times

Reduced tool or machine efficiency

Frequent alarms or warning lights

Inconsistent air supply

Troubleshooting

Low pressure in screw air compressors can result from several factors. You need to identify the root cause to restore optimal performance. Begin by inspecting the exhaust valve and pressure switch. Check for leaks in the air supply line. Examine the air filters and oil separator for blockages. Verify the intake valve opens fully. Assess whether your air demand exceeds the compressor’s capacity.

Leading causes of low pressure:

Faulty exhaust valve (failure to close during loading)

Pressure switch set too low

Faulty pressure gauge

Faulty pressure switch

Air supply line leaks

Air demand exceeds supply

Clogged air filters

Faulty or malfunctioning pressure regulator

Clogged oil separator

Intake valve not fully opening

💡 Tip: Use a pressure gauge and leak detector to pinpoint issues quickly. Addressing these problems early prevents further damage and costly downtime.

Maintenance Advice

Regular maintenance helps you avoid low pressure problems. Clean or replace air filters and oil separators as recommended. Inspect valves and pressure switches for wear. Monitor system pressure with reliable gauges. Smart technology and digital monitoring now allow you to track compressor performance in real time. These advancements help you predict maintenance needs and maintain stable air pressure, which is essential for manufacturing efficiency. Variable speed drives also adjust compressor speed to match air demand, improving energy efficiency and reducing power consumption.

🛠️ Pro Tip: Schedule routine inspections and use high-quality parts from trusted brands like Sollant. Consistent care ensures your screw air compressor delivers reliable pressure and supports smooth operations.

Excessive Noise

Causes

You may notice your screw air compressor producing unusual or loud sounds during operation. While screw compressors typically run quieter than piston models, excessive noise signals a problem that needs your attention. Most noise issues stem from mechanical faults, loose parts, or insufficient lubrication.

Description | Solution | |

|---|---|---|

Loose Belt | Burnt odor, abnormal friction noise, fluctuating current due to slippage. | Adjust belt tension, replace if needed. |

Oil Starvation | Screeching from direct metal contact due to low lubrication. | Check oil level, replace oil filter. |

Faulty Inlet Valve | Leakage or vibration generating noise. | Replace or adjust the valve. |

Motor Bearing Failure | Loud rolling or screeching from worn or dry bearings. | Replace or relubricate bearings. |

Rotor Assembly Issues | Jamming or screeching from foreign objects or excessive clearance. | Overhaul and readjust clearances. |

Damaged Muffler System | Increased noise from degraded or loose muffler components. | Inspect and tighten muffler parts. |

You might also hear:

Metallic clashing from loose components

Rhythmic knocking linked to bearing wear

High-pitched squealing from belt slippage

Airflow whistling caused by valve resistance

Solutions

You can resolve most noise problems by inspecting and maintaining key components. Start by checking the belt tension and replacing worn belts. Examine the oil level and quality, then change the oil filter if needed. Inspect the inlet valve for leaks or vibration. Listen for bearing noise and replace or lubricate bearings as required. Remove any foreign objects from the rotor assembly and ensure proper clearances. Tighten or replace muffler components to reduce exhaust noise.

🔧 Tip: Regularly scheduled maintenance prevents most noise issues and extends the life of your compressor.

Sollant Support

Sollant designs screw air compressors with insulated cabinets and advanced engineering to minimize noise. You benefit from quieter operation, often allowing normal conversation near the machine. Sollant’s technical team can help you diagnose and fix persistent noise problems. For best results, use genuine Sollant parts and follow the recommended maintenance schedule. If you need further assistance, visit Sollant’s official website for expert support and resources.

🛡️ Note: Addressing noise early protects your equipment and ensures a safe, productive work environment.

Overheating

Warning Signs

You can spot overheating in your screw air compressor by watching for several clear indicators. The most obvious sign is a sudden shutdown during operation. Many compressors have automatic shutdown features that activate when temperatures reach 220℉ to 230℉. You may also notice the compressor running hotter than usual, with surface temperatures exceeding 100℉ to 110℉. Oil temperature readings above 200℉ signal trouble, especially if they stay high for long periods. Warning lights or alarms on the control panel often alert you to rising temperatures. You might feel excessive heat near the motor or smell burnt oil, which points to oil degradation.

⚠️ Tip: Ideal operating temperatures for screw compressors range from 50°F to 85°F. Oil should stay between 175°F and 190°F for best performance.

Fixes

You can address overheating by targeting the root causes. Start by checking the ambient temperature around your compressor. High return air temperature raises both suction and exhaust temperatures. For every 1°C increase in return air temperature, the exhaust temperature can rise by 1 to 1.3°C. Inspect the cooling system for blockages or dirty radiators. Clean or replace clogged filters and ensure the cooling fan works properly. Examine the oil level and quality. Replace degraded oil and use the correct grade recommended by the manufacturer. Electrical heating inside the motor cavity can also raise cylinder suction temperature. Monitor the motor’s power consumption and address any abnormal increases.

Cause | Explanation |

|---|---|

High Return Air Temperature | Raises suction and exhaust temperatures, leading to overheating. |

Electrical Heating | Increases cylinder suction temperature due to heat from the motor. |

High Compression Ratio | Results in higher exhaust temperature; reduce by adjusting suction and exhaust pressures. |

🛠️ Note: Always disconnect power before performing maintenance to ensure safety.

Cooling System Care

You keep your compressor cool by maintaining the cooling system. Clean the radiator and air passages regularly to prevent dust buildup. Check the cooling fan for proper operation and replace it if needed. Inspect the oil cooler and water cooler for blockages or leaks. Use high-quality oil and change it at recommended intervals to avoid oil breakdown. Monitor temperature sensors for accuracy and replace faulty units promptly. Sollant recommends following a strict maintenance schedule and using genuine parts for optimal cooling performance.

🧊 Pro Tip: Regular cooling system checks prevent overheating and extend your compressor’s lifespan. For advanced support, Sollant’s technical team stands ready to help you maintain peak efficiency.

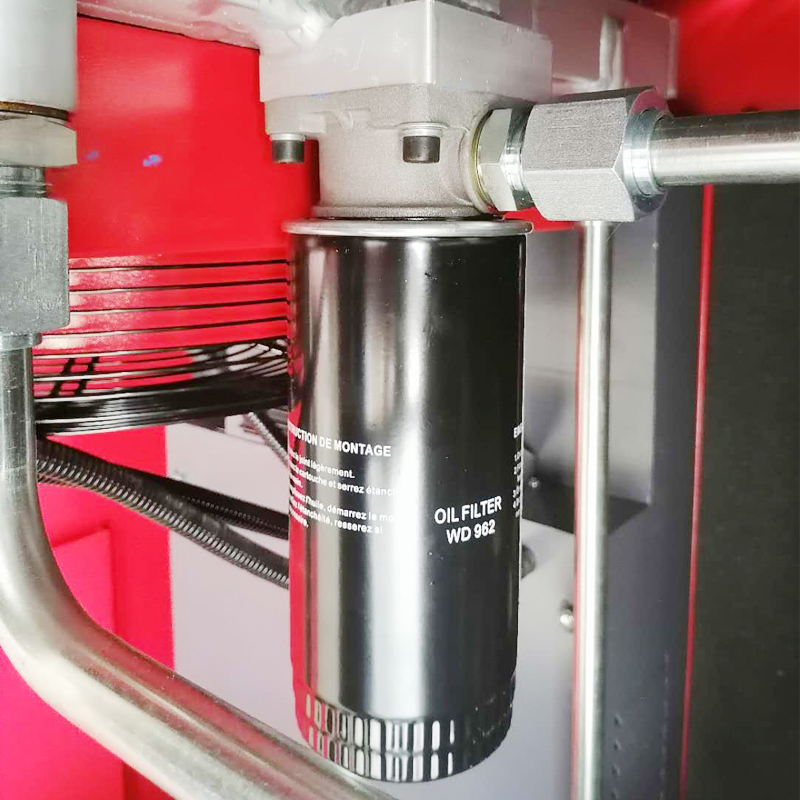

Oil Leaks

Detection

You can spot oil leaks in screw air compressors by observing several clear signs. Oil stains often appear around the base, joints, or beneath the compressor. You may notice a drop in oil level on the gauge, or see puddles forming under the machine. Sometimes, you detect a burnt oil smell or find residue near seals and connections. Regular visual inspections help you catch leaks early. Use a flashlight to check hard-to-see areas, especially around gaskets, oil lines, and the separator tank.

🔍 Tip: Monitor oil consumption rates. A sudden increase often signals a leak or internal issue.

Repair

You address oil leaks by targeting the root cause. Begin by identifying the source. Common causes include:

Aging or damaged seals (O-rings, oil seals)

Loose or damaged piping connections

Faulty oil filters or separators

Excessive oil level

Cracked or worn oil lines

Oil system blockage from dirt or impurities

Poor assembly or uneven bolt tightening

High temperature or overload operation

Once you locate the leak, replace worn seals and tighten connections. Clean or replace clogged oil filters and separators. Drain excess oil to maintain proper levels. Inspect oil lines for cracks and swap out damaged sections. If you find assembly issues, retighten bolts and ensure sealing surfaces are level. Always use manufacturer-recommended parts for repairs.

Problem Area | Solution |

|---|---|

Seals and Gaskets | Replace with new components |

Oil Lines | Repair or replace as needed |

Oil Filter/Separator | Clean or install new units |

Connections | Tighten or reseal joints |

🛠️ Note: Disconnect power before repairs to ensure safety.

Prevention

You prevent oil leaks by following a strict maintenance routine. Inspect seals, gaskets, and oil lines regularly. Keep oil levels within recommended limits. Use high-quality oil and filters to reduce contamination. Avoid overloading the compressor or running it at high temperatures. Ensure all connections remain tight and assembly meets manufacturer standards. Sollant recommends using advanced filter materials and nano-plated components for superior durability and leak resistance.

Schedule routine inspections

Replace aging seals and gaskets promptly

Maintain proper oil levels

Use genuine Sollant parts for best results

💡 Pro Tip: Consistent maintenance and quality components help you avoid costly oil leaks and keep your screw air compressor running efficiently.

High Oil Use

Symptoms

You may notice your screw air compressor requires frequent oil top-ups. The oil level drops faster than expected. You see increased oil consumption on the gauge or in maintenance logs. Sometimes, you spot oil residue near the separator or exhaust. Operators often report abnormal oil smells or visible smoke from the exhaust. These symptoms indicate excessive oil use and signal underlying issues that need attention.

Tip: Monitor oil levels daily. Sudden drops often point to leaks or internal carryover.

Solutions

You can address high oil use by identifying and correcting the root causes. Several factors contribute to excessive oil consumption. The table below summarizes the most common reasons and recommended actions:

Cause | Solution |

|---|---|

Restricted air intake | Replace or clean air filter |

High operating temperature | Lower ambient temperature, check cooling |

Oil carryover from separator | Inspect and replace separator if needed |

Locate and repair leaks | |

Contaminants degrading oil quality | Seal intake filter, improve filtration |

If your compressor runs above the recommended temperature for your oil, the oil breaks down faster. For every 18°F increase above the recommended temperature, oil life is cut in half. Dirty environments require more frequent air filter changes—sometimes before the standard 2,000-hour interval. Maintaining the correct oil level prevents inadequate lubrication and reduces wear.

💡 Note: Always use manufacturer-approved oil and parts for repairs.

Maintenance

You maintain optimal oil usage by following a strict schedule. Change mineral oils and blends every 4,000 operating hours. Synthetic oils last up to twice as long. Replace oil at least every 6 to 12 months, regardless of hours, and more often in dusty or dirty conditions. Regularly inspect intake filters and separators. Clean or replace them as needed. Monitor for contaminants such as dust, dirt, and acid gases. Proper sealing of intake filters prevents particulate matter from entering the system.

Check oil levels daily

Change oil at recommended intervals

Replace air filters and separators regularly

Inspect for leaks and carryover

Use high-quality oil and genuine parts

Sollant recommends using advanced filter materials and nano-plated components to extend oil life and reduce consumption. You can find more maintenance resources and support on Sollant’s official website.

🛠️ Pro Tip: Consistent oil management keeps your screw air compressor running efficiently and reduces operating costs.

Air Leaks

Finding Leaks

You often face air leaks in screw air compressors. These leaks can hide in several key locations. You should check the following areas during your inspection:

Air end seals: These seals wear out over time and allow air to escape.

Oil cooler and lines: High temperatures and pressure make these spots vulnerable to leaks.

Oil separator: Seals and gaskets around the separator can develop leaks, especially as they age.

You may hear a faint hissing sound or notice a drop in system pressure. Sometimes, you see oil residue near joints or connections. Use a leak detector or soapy water to spot escaping air. Bubbles form where leaks exist. Early detection helps you avoid bigger problems.

🔍 Tip: Regular inspections help you catch leaks before they impact your operations.

Repair Steps

You need to act quickly when you find an air leak. Start by shutting down the compressor and disconnecting the power. Clean the area around the leak. Replace worn seals, gaskets, or damaged lines. Tighten loose fittings and connections. If you find a leak in the oil separator, install a new gasket or seal. Always use manufacturer-approved parts for repairs.

Table: Common Leak Locations and Actions

Location | Action |

|---|---|

Air end seals | Replace worn seals |

Oil cooler/lines | Repair or replace damaged lines |

Oil separator | Install new gaskets/seals |

Test the system after repairs. Monitor pressure and listen for any remaining leaks. Proper repairs restore efficiency and prevent further damage.

🛠️ Note: Always follow safety procedures and use the right tools for each repair.

Leak Prevention

You can prevent air leaks with routine maintenance. Inspect seals, gaskets, and lines regularly. Replace aging components before they fail. Keep connections tight and clean. Use high-quality parts to reduce the risk of leaks. Air leaks decrease system efficiency, increase energy costs, and shorten equipment lifespan. Manufacturing tolerances can cause leaks, but regular care minimizes their impact.

Schedule regular leak checks

Use advanced filter materials and durable seals

Monitor system pressure for early warning signs

💡 Pro Tip: Preventing leaks saves energy, lowers costs, and extends the life of your screw air compressor.

Moisture Issues

Signs

You often notice moisture problems in your screw air compressor when water collects in the air lines or tanks. You may see rust forming on metal surfaces. Filters clog more quickly than usual. Air tools sometimes sputter or lose power. Operators report a musty smell or visible water droplets in the compressed air. These signs indicate that excess moisture has entered your system and threatens both performance and equipment lifespan.

💧 Tip: Watch for rust, clogged filters, and water in the air lines. These symptoms signal moisture buildup and require immediate attention.

Solutions

You can tackle moisture issues by understanding their root causes and applying targeted fixes. The table below outlines common sources of moisture and practical solutions:

Cause | Explanation | Solution |

|---|---|---|

Humidity in the Intake Air | High humidity levels in the intake air lead to excess moisture entering the compressor. | Install an air dryer or moisture separator to reduce humidity. |

Condensation Due to Temperature Fluctuations | Frequent temperature changes cause condensation within the compressor. | Insulate the compressor room and maintain stable temperatures. |

Short Operating Cycles | Short cycles prevent the compressor from reaching optimal temperature, reducing moisture evaporation. | Allow longer run times to reach ideal operating temperature. |

Insufficient Draining and Maintenance | Water and contaminants accumulate without regular draining. | Set up a schedule to drain the oil-gas tank and replace filters regularly. |

Faulty Separation System | Malfunctioning oil-water separators fail to filter moisture. | Inspect and replace the separator during routine maintenance. |

Low Ambient Temperatures | Cold air increases condensation inside the compressor. | Use a temperature-controlled environment for the compressor. |

Faulty or Inefficient Dryer System | Malfunctioning dryers do not remove enough moisture. | Ensure the dryer matches your compressor’s needs and maintain it properly. |

Excessive moisture can cause rust in compressor components. You may face filter clogs that block airflow and reduce efficiency. Performance drops, and maintenance costs rise as moisture damages your equipment.

Rust forms on metal parts.

Filters clog and restrict airflow.

Maintenance costs increase due to reduced machinery performance.

Filter Care

You protect your screw air compressor from moisture damage by caring for the filters. Inspect air filters and oil-water separators regularly. Replace clogged or worn filters before they fail. Clean filter housings to prevent buildup of water and contaminants. Use high-density filter materials with nano-plating for better moisture resistance and durability. Sollant recommends setting a strict maintenance schedule and using genuine parts to ensure optimal filtration. Proper filter care keeps your compressor running smoothly and extends its service life.

🛠️ Pro Tip: Regular filter checks and timely replacements prevent moisture problems and safeguard your investment.

Pressure Fluctuations

Symptoms

You may notice your screw air compressor delivers inconsistent air pressure. Tools and machines sometimes lose power or operate erratically. Pressure gauges show rapid swings above and below your setpoint. Operators often report sudden drops or spikes in air supply. Warning lights or alarms may activate unexpectedly. These symptoms disrupt production and can damage sensitive equipment.

Common signs of pressure fluctuations include:

Pressure gauge readings that jump or fall quickly

Air tools losing force or stalling

Frequent alarms or warning indicators

Inconsistent performance across shifts

⚠️ Tip: Monitor your pressure gauge during operation. Sudden changes often signal underlying problems that need immediate attention.

Fixes

You can address pressure fluctuations by targeting the most frequent causes. Begin by inspecting the pressure control system. Poor pressure control often leads to high fluctuations, especially if you do not monitor the system carefully. Check all attachments and piping for restrictions or faults. Improper connections force the compressor to overcompensate, resulting in excessive pressure swings. Tiny leaks may go unnoticed, causing operators to raise the pressure unnecessarily. This practice increases overall air pressure and worsens fluctuations.

Typical reasons for pressure fluctuations:

Poor pressure control or monitoring

Pressure restrictions from faulty attachments or piping

Unnoticed leaks leading to unnecessary pressure increases

Table: Troubleshooting Pressure Fluctuations

Cause | Solution |

|---|---|

Poor pressure control | Calibrate or replace pressure controllers |

Faulty attachments/piping | Inspect and repair connections |

Tiny leaks | Locate and seal leaks |

You should test the system after repairs. Watch for stable pressure readings and consistent tool performance. Always use manufacturer-recommended parts for replacements.

Regular Checks

You keep your screw air compressor reliable by performing regular checks. Inspect pressure controllers and gauges weekly. Examine all piping and attachments for signs of wear or damage. Use a leak detector to find and fix small leaks before they cause bigger problems. Sollant recommends scheduling monthly system audits and using advanced monitoring technology for real-time pressure tracking.

Check pressure controllers and gauges weekly

Inspect piping and attachments for damage

Use leak detectors for early leak detection

Schedule monthly system audits

🛠️ Pro Tip: Consistent monitoring and maintenance prevent pressure fluctuations and protect your equipment. Reliable pressure supports smooth operations and reduces costly downtime.

Electrical Faults

Common Issues

You often encounter electrical faults in screw air compressors. These problems can disrupt your operations and lead to costly downtime. The most frequent electrical issues include:

Power Supply Abnormality: Blown fuses or unstable voltage prevent your compressor from starting. You may notice the control panel remains dark or the motor fails to engage.

Motor Failure: A stuck rotor or damaged motor winding requires immediate attention. You might hear unusual noises or see the motor overheat.

Control Circuit Failure: Poor contact at the start button or aging relays can cause operational failures. You may experience intermittent starts or sudden shutdowns.

⚡ Tip: Regularly inspect electrical components to catch faults early and avoid unexpected breakdowns.

Safe Repairs

You must prioritize safety when repairing electrical faults. Always disconnect the power supply before starting any work. Use insulated tools and wear protective gloves. Begin by checking the main power source for blown fuses or voltage irregularities. Replace damaged fuses and stabilize the voltage if needed. Inspect the motor for signs of overheating or physical damage. If you find a stuck rotor or faulty winding, contact a qualified technician for repairs. Examine the control circuit, focusing on the start button and relays. Clean contacts and replace aging components to restore reliable operation.

Table: Electrical Faults and Safe Repair Actions

Fault Type | Safe Repair Action |

|---|---|

Power Supply Abnormality | Replace fuses, stabilize voltage |

Motor Failure | Inspect, repair, or replace motor |

Control Circuit Failure | Clean contacts, replace relays |

🛠️ Note: Never attempt complex electrical repairs without proper training. Professional support ensures safety and quality.

System Care

You keep your screw air compressor running smoothly by maintaining the electrical system. Schedule routine inspections for wiring, connectors, and control panels. Clean dust and debris from electrical enclosures to prevent overheating. Use high-quality components and follow manufacturer guidelines for replacements. Sollant recommends regular system audits and using advanced monitoring technology to detect faults early. Reliable electrical care reduces downtime and extends equipment life.

Inspect wiring and connectors monthly

Clean control panels and enclosures

Use genuine Sollant parts for replacements

💡 Pro Tip: Preventive electrical maintenance protects your investment and supports uninterrupted production.

Frequent Shutdowns

Patterns

You may notice your screw air compressor shuts down more often than expected. These shutdowns often follow a pattern. The compressor might stop suddenly after running for only a short time. Sometimes, you see oil spraying from the air inlet when the machine halts. You may also observe the compressor tripping automatically, especially during periods of high demand or temperature spikes. The control panel may display warnings about low exhaust pressure or excessive heat. These patterns signal underlying issues that need your attention.

⚠️ Tip: Track shutdown times and conditions. Patterns help you pinpoint the root cause faster.

Troubleshooting

Frequent shutdowns usually result from a few key problems. Addressing these issues quickly restores reliable operation. Here are the most common causes:

Oil spraying from the air inlet often points to a faulty air inlet valve or a malfunctioning oil cut-off solenoid valve.

Automatic tripping can happen due to power supply problems or high exhaust temperatures. Low lubricating oil, a blocked cooler, or a bad temperature control valve often cause these shutdowns.

Low exhaust pressure may occur if the intake valve does not open fully or if external air demand increases suddenly.

Excessive temperature will force the compressor to stop automatically if the exhaust temperature rises above 120°C.

Frequent shutdowns can hurt your facility’s productivity. You may see reduced capacity, which leads to insufficient lubrication as oil breaks down. Short cycling puts extra wear on the compressor, causing early failures. If you do not maintain the system during shutdowns, you risk damaging both the compressor and connected components.

Table: Common Causes and Solutions for Frequent Shutdowns

Cause | Solution |

|---|---|

Faulty air inlet or oil cut-off valve | Inspect and replace faulty valves |

Power supply or high temperature | Check power, oil level, and cooling system |

Intake valve not fully open | Adjust or repair intake valve |

Excessive temperature | Improve cooling, check temperature controls |

Sollant Service

Sollant provides expert support to help you resolve frequent shutdowns. You can contact Sollant’s technical team for troubleshooting advice and genuine replacement parts. Sollant recommends regular inspections of valves, oil levels, and cooling systems to prevent shutdowns before they start. Using high-quality components from Sollant ensures your compressor runs smoothly and reliably. For more resources and personalized service, visit Sollant’s official website or reach out to their support team.

🛠️ Pro Tip: Preventive maintenance and timely repairs keep your screw air compressor running at peak performance and minimize costly shutdowns.

Air Compressor Maintenance Screw Air Compressor

Routine Tasks

You keep your screw air compressor running efficiently by following a consistent air compressor maintenance screw air compressor schedule. Daily checks help you catch small issues before they become major problems. You should inspect oil levels, look for leaks, and verify that controls operate correctly. Monitoring temperature readings and listening for unusual noises or vibrations ensures early detection of faults. You also need to check air filters for blockages and review operating pressure levels. Regularly examine hoses, connections, and safety relief valves for signs of wear or damage.

Here is a table outlining essential routine maintenance tasks and their recommended frequency:

Maintenance Task | Frequency |

|---|---|

Check compressor oil level | Daily |

Inspect for leaks | Daily |

Verify proper operation of controls | Daily |

Check the air filter for blockages | Daily |

Monitor temperature readings | Daily |

Observe for unusual noise or vibration | Daily |

Examine safety relief valves | Daily |

Inspect hoses and connections | Daily |

Review operating pressure levels | Daily |

Change oil and oil filters | Every 2000 to 8000 hours |

Clean or replace air filter | As needed |

Replace air oil separator element | As per schedule |

Clean heat exchanger surfaces | As per instructions |

Consistent air compressor maintenance screw air compressor routines extend equipment life. Well-maintained compressors often last 10 to 20 years or more. You avoid costly downtime and emergency repairs by catching problems early.

Sollant Maintenance Solutions

Sollant recommends a proactive approach to air compressor maintenance screw air compressor. You benefit from using high-quality parts and advanced filter materials, which resist chemical solvents and high temperatures. Sollant’s nano-plated components offer superior durability and help prevent leaks and contamination. You should follow the manufacturer’s maintenance schedule, including regular oil changes, filter replacements, and alignment checks.

Regular maintenance lowers the risk of breakdowns, optimizes energy use, and reduces total ownership costs. You prevent major failures and keep your compressor running at peak efficiency. Sollant provides detailed guides and technical support to help you maintain your system. For more resources and personalized advice, visit Sollant’s official website.

🛠️ Tip: Routine air compressor maintenance screw air compressor tasks and genuine Sollant parts protect your investment and ensure reliable performance.

You protect your business when you identify and repair screw air compressor problems quickly. Regular air compressor maintenance screw air compressor routines help you avoid costly breakdowns and keep your system efficient. Industry experts highlight several key points:

Routine inspections and timely repairs prevent downtime.

Regular maintenance extends compressor life and ensures safety.

Inspections detect issues before they become serious.

Leading manufacturers recommend that you monitor and replace filters, check oil levels, inspect drive belts, and follow the maintenance schedule. Choose a reliable brand like Sollant to support your operations. Take action now to keep your compressors running smoothly. If you need expert help, Sollant’s team stands ready to assist you.

FAQ

What maintenance tasks should you perform daily on a screw air compressor?

You should check oil levels, inspect for leaks, monitor temperature readings, and listen for unusual noises. Examine air filters and review pressure gauges. These daily checks help you catch problems early and keep your compressor running efficiently.

How often should you replace the air filter and oil separator?

Replace the air filter and oil separator according to your manufacturer’s schedule. Most experts recommend changing filters every 2,000 to 8,000 hours. Replace them sooner if you operate in dusty or dirty environments.

What causes frequent shutdowns in screw air compressors?

Frequent shutdowns often result from overheating, low oil levels, faulty valves, or electrical faults. You should inspect cooling systems, oil supply, and control panels regularly to prevent unexpected stops.

Can you repair a screw air compressor yourself, or should you call a professional?

You can handle basic maintenance and minor repairs if you follow safety guidelines. For complex electrical or mechanical issues, contact a professional technician or reach out to Sollant’s support team for expert assistance.

How do you prevent moisture problems in your compressed air system?

Install an air dryer or moisture separator. Drain tanks and replace filters regularly. Maintain stable room temperatures and monitor humidity levels. These steps help you avoid rust, clogged filters, and performance loss.